railway-international.com

02

'24

Written on Modified on

Knorr Bremse: New generation of KEf valves support modern freight car operations

It also lays the foundations for digitizing the freight train as the next industry milestone. In operation, the valves make an excellent impression thanks to very high levels of availability.

In the decades after the KE valve was first launched in 1953, around 500 variants appeared on the market. In each case, this involved designing and manufacturing a more or less unique relay valve to match each individual specification, complete with its own part number. One of the reasons for developing the new KEf generation from scratch was to clear up this proliferation of variants. Although the new range has been reduced to just 50 different configurations, the KEf family boasts an even broader range of adjustable settings for project specific applications.

The jewel in the crown is the modular KEf/KRf system,with its focus on the 90 percent of characteristic curves with a gradient between 0.6 and 1.5 typically achievable in the field. Despite a few outliers, the developers made this decision for very good reasons: “It meant we could reduce the number of T springs to ten without having to ask operators to accept restrictions on standard freight car characteristic maps,” explains Thomas Petter, who heads the KEf development team. “The characteristic curves are easy to adjust mechanically at the production stage.”

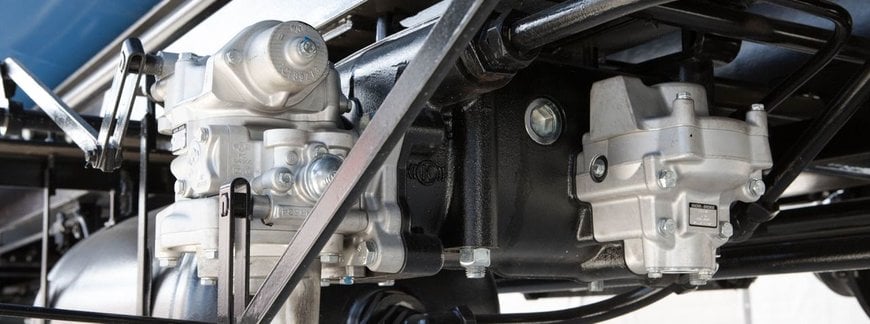

In particular, whereas the only way to install the “old” KE valve in space-critical low-floor applications was to build a unique, dedicated solution for each application, the new KEf valve obviates this problem – even in its standard configuration. “We’ve developed the platform in such a way that you can mount the distributor and relay valves separately on the carrier,” adds Petter. When it comes to maintenance and spare parts management, the benefits of this design show up in another, not insignificant advantage: It is now easy to independently remove and replace the small, lightweight distributor and relay valves. The valve carrier itself has no service able parts, so it simply stays on the vehicle while the valves are being serviced.

Retrofittable actuators open the door to new functions in the future But the KEf valve generation was also developed as a key element in the urgently needed digitization of the freight train. The valve’s new data channel, which includes an interface for collecting pneumatic operating data, will act as the cornerstone of applications ranging from condition-based monitoring – including continuous brake status monitoring by train drivers – through to automated brake testing for speeding up train preparation.

Designed as a platform that will last for decades, the valve also supports all the automation enhancements currently under discussion by the Digital Freight Train developers currently involved in “Flagship Area 5” of the Europe’s Rail Joint Undertaking technology program.

The ability to integrate actuators opens the door to a whole raft of new functions in the future, such as a networked electropneumatic brake. High levels of availability, e.g. on state-of-the-art T3000 pocket wagons.

More and more vehicle manufacturers and operators are opting to equip their new vehicles with systems based on the new KEf platform rather than a conventional KE variant.

By the end of last year, for example, more than 3,000 KEf and KRf valves had been fitted to some 400 state-of-the-art T3000 pocket wagons built by Swiss rail car designer Ferriere Cattaneo. The company has been very impressed by the valves’ high availability levels. And it was the KEf’s compact design that made it possible to install the valves in the manufacturer’s very exacting, ultra-low T3000 “pocket wagon” configuration speeding up train preparation.

www.knorr-bremse.com