railway-international.com

26

'25

Written on Modified on

GRAW Wins Major Contract for Automated Track Inspection in Poland

P.U.T. GRAW Sp. z o.o., a specialist in track measurement systems and part of the Goldschmidt Group, has signed a major contract with PKP Polish Railway Lines (PKP PLK) to supply innovative solutions for automating track inspection.

www.goldschmidt.com

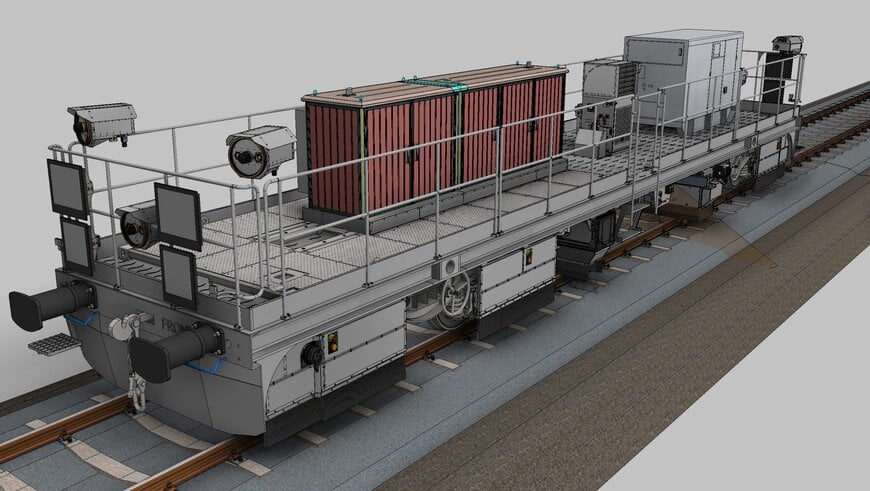

3D visualisation of one of the new inspection vehicles for PKP PLK with sensor and camera technology © Goldschmidt

Under the framework contract, GRAW will deliver inspection vehicles equipped with cutting-edge sensor and camera technology, paired with specially developed software for precise, automated monitoring of track conditions. This combination will replace manual inspections with an automated, data-driven process – increasing both safety and efficiency in rail operations.

The inspection vehicles will record a comprehensive set of parameters, including track and rail geometry, turnout geometry, ballast bed condition, rail temperature and an extensive video inspection system for the track infrastructure. Thanks to integrated AI capabilities, the system’s knowledge base will expand continuously, with each inspection enhancing precision and reliability.

In the initial phase, by the end of 2028, one inspection vehicle, two local servers and seven local workstations will be delivered and tested in a pilot area. Over the eight-year project duration, up to nine inspection vehicles are planned for different regions of Poland, along with 23 servers and 60 workstations for data analysis. The contract also covers five years of maintenance and support as well as comprehensive service and training.

www.goldschmidt.com

Under the framework contract, GRAW will deliver inspection vehicles equipped with cutting-edge sensor and camera technology, paired with specially developed software for precise, automated monitoring of track conditions. This combination will replace manual inspections with an automated, data-driven process – increasing both safety and efficiency in rail operations.

The inspection vehicles will record a comprehensive set of parameters, including track and rail geometry, turnout geometry, ballast bed condition, rail temperature and an extensive video inspection system for the track infrastructure. Thanks to integrated AI capabilities, the system’s knowledge base will expand continuously, with each inspection enhancing precision and reliability.

In the initial phase, by the end of 2028, one inspection vehicle, two local servers and seven local workstations will be delivered and tested in a pilot area. Over the eight-year project duration, up to nine inspection vehicles are planned for different regions of Poland, along with 23 servers and 60 workstations for data analysis. The contract also covers five years of maintenance and support as well as comprehensive service and training.

www.goldschmidt.com