railway-international.com

26

'24

Written on Modified on

ÖBB Rail Cargo Group puts Donau Chemie's salt on track with new wagons

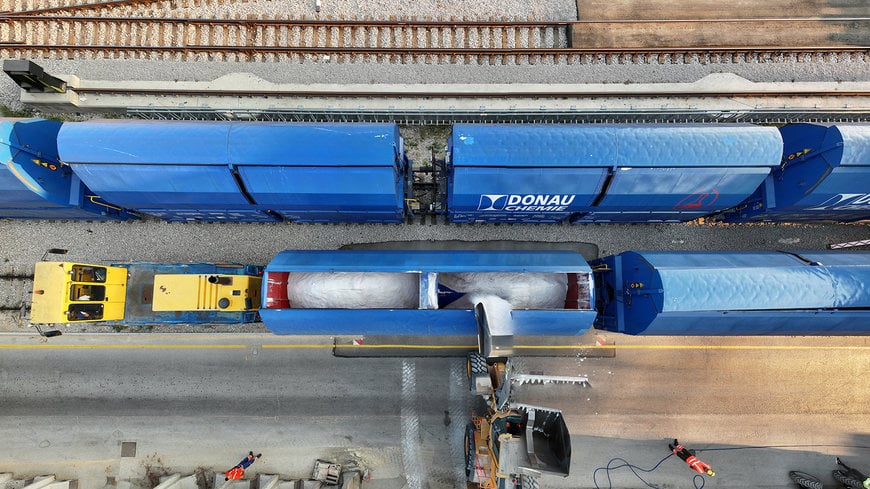

The ÖBB Rail Cargo Group (RCG), in collaboration with innovative equipment companies and Donau Chemie, has designed a robust TALNS wagon, ranking among the most advanced in Europe.

www.oebb.at

Salt Transports Require Specialised Equipment

Transporting large quantities of salt from A to B poses very special challenges. Salt sticks to the wagon during loading and unloading and its corrosive properties put a strain on the wagon material, both on the inside and on the outer surfaces. As a result, salt wagons age quickly and have to be repaired or replaced more often than other wagons. A durable coating is therefore essential to ensure their longevity and functionality.

“This is exactly where we come in,” explains Christoph Grasl, Member of the Board at ÖBB Rail Cargo Group (RCG). “For the first time, in collaboration with Donau Chemie, we have developed a highly robust TALNS wagon that is one of the most advanced in Europe.” Grasl adds, “Customers such as Donau Chemie benefit greatly from these innovative wagons, enabling them to further accelerate the shift from road to rail.”

Unloading at the Push of a Button

The first brand-new TALNS wagons were handed over directly at the Donau Chemie plant in Brückl (Carinthia) in the spring and are already in use. They are extremely robust to cope with the raw material salt and also offer many other advantages: for example, unloading is semi-automatic at the touch of a button using pneumatics, which significantly reduces the workload and strain on employees and also makes a significant contribution to increasing work safety.

One Train Replaces 44 Trucks

RCG transports salt, which was previously mainly carried by trucks, from Koper in Slovenia and Ebensee in Upper Austria to Donau Chemie’s plant in Brückl, where it is used in electrolysis. The transports by rail significantly reduce CO2 emissions. “The new salt wagons were specifically designed to meet our needs and are much more efficient in their construction and functionality than any other equipment currently available on the market – and on top of that, they’re sustainable,” explains Richard Fruhwürth, CEO of Donau Chemie AG. “A full train can carry approximately 1,100 tonnes of salt. It would take 44 trucks to transport this amount of tonnes. By using environmentally friendly rail, we are making a significant contribution to climate protection,” Fruhwürth adds. The exemplary supply concept is an important step toward the "modal shift" from road to rail.

Cooperation With a Role Model Function

The long-standing cooperation between Donau Chemie and the Rail Cargo Group impressively demonstrates that economic efficiency and sustainability can harmonise perfectly in logistics. The key to this lies in a customised transport solution with state-of-the-art equipment. Thanks to the innovative TALNS wagon technology, the switch to rail transport made economic sense for both sides despite the erosive properties of salt and is a step towards CO2-reduced logistics solutions that sustainably reduce the burden on the environment. Because their success shows that they are on the right track, Donau Chemie and RCG have extended their co-operation for a further ten years.

Major Player in the Chemical Industry

The Donau Chemie Group is a family-owned company, a leading player in the chemical industry and operating in twelve countries worldwide. The Group focuses on the development and production of industrial chemicals, which are used in many industrial processes and applications, as well as the distribution of chemicals in Central and Eastern Europe. In the field of environmental technology, the Donau Chemie Group produces activated carbon as well as precipitants and flocculants for the treatment of water. For more than ten years, Donau Chemie has relied on RCG's logistics expertise to ensure the reliable supply of its production sites – and in the spring, salt transport was significantly expanded with the new wagons.

www.obb.com