Maximal Sliding Door Performance in Passenger Trains with Miniature Shock Absorbers

This case shows that service can be the best door opener. It describes how the subsidiary of BIBUS AG in Hungary and ACE Stoßdämpfer GmbH are helping a specialist in rail-guided wagon and bus equipment to find a sustainable damping solution for its pneumatically operated sliding doors.

With the growing number of passengers in local and long-distance passenger transport, the importance of safe, sustainable designs in rail car construction is increasing. There are numerous specialist companies in this area, which in turn work with specialized suppliers. In Hungary, one of these companies is Metal 99 Ltd. from Dabas. The engineers from the district 50 km south of Budapest are in contact with important transport companies at home and abroad, including BKV Budapest Transport Corporation and MÁV Hungarian Railways, among others.

“In particular, our windows and doors, which are manufactured in-house, enable public transport to be as sophisticated as it is safe,” says managing director Péter Garajszki. The family business, which started in 1991 with the repair of high-voltage devices, windows and doors as well as the production of door systems for public transport, is developing dynamically. "Today, with a team of over 100 persons, we also manufacture windows with a specially designed profile system and are known for our sliding doors as well as for electrically and pneumatically operated interior and exterior sliding and pivoting doors, which we design and adapt according to the specific wishes of our customers," explains Péter Garajszki, adding that his team also designed the doors for the Hungarian high-speed trains, which are integrated into the new Inter City carriages.

Lightweight, compound aluminum separating and passage doors in flat and bent designs are part of Metal 99’s product portfolio for European railway companies

Metal 99 has been successfully cooperating with BIBUS in Hungary for many years in pneumatics and other areas. The Swiss corporation BIBUS AG and its Hungarian subsidiary are first addresses in Europe for full service when it comes to hydraulic and pneumatic drive and control systems. Since the group is also known as a trusted supplier of complete systems, the request to BIBUS Hungary in this case was whether they could supply a large number of high-quality industrial shock absorbers. The goals: to ensure that the door opening and closing system for numerous wagons is as sustainable and reliable in the end positions as possible and to safeguard continuous operation by also protecting the doors against possible vandalism.

Metal 99’s sliding doors are made upon special customer requests and feature compact, integrated actuators as well as powerful miniature shock absorbers for safety and comfort

Better safe than sorry

Dávid Garajszki, technical director at Metal 99, and his team are experienced in using high-quality materials and components as standard equipment for their constructions. This is the reason why they re-evaluated the original design of the trains which at an earlier stage considered shock absorbers made in China to be integrated in the end position of the doors. Due to the end user’s location in the Middle East and the importance of the project, Dávid Garajszki opted to use shock absorbers with proven reliability and of higher quality in order to prevent possible failures once the whole construction was delivered to the customer. Therefore, they addressed their pneumatics specialist BIBUS who they know offers a wide range of hydraulic products. Nobert Turi, BIBUS' sales manager, remembers: "My colleague at Metal 99 had doubts about the Chinese quality and asked for advice. So I recommended to him the shock absorbers from ACE, which we sell exclusively in Hungary, in the same dimensions and with comparable technical data such as those of the other dampers."

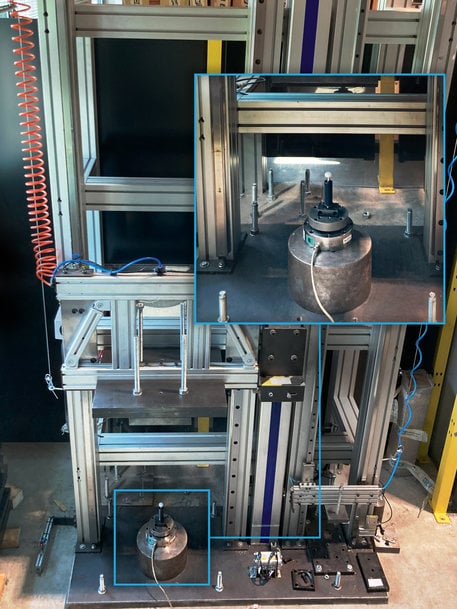

ACE validates customer-specific values of maximum energy capacities of small shock absorbers previously determined for emergency stops with a series of drop tests

No sooner said than done, and after free sampling and testing, Dávid Garajszki and the team at Metal 99 were convinced of the long-term qualities of the hydraulic components supplied by BIBUS. However, their price was higher than that of the Chinese competitors. Norbert Turi then took a closer look at the shock absorbers used at first and also at the application. For the 55 kg that the sliding doors weigh and which are moved at a maximum speed of 2 m/s, dampers with energy absorption of 59 Nm/cycle were initially selected. Since he knew from his long experience of cooperating with ACE that the company from Langenfeld in Germany takes high safety tolerances into account for their miniature and industrial shock absorbers, he made a new suggestion to the engineers at Metal 99.

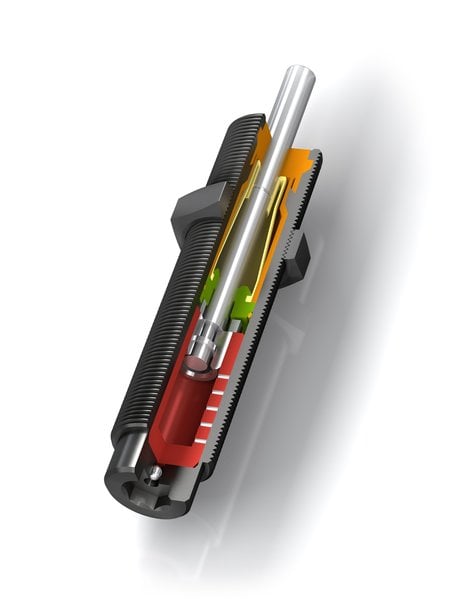

Due to a hermetically sealed rolling diaphragm in each absorber, ACE’s MC150 to MC600 product family is suitable for an exceptional high lifetime of use with up to 25 million cycles

How drop tests and safety tolerances make the difference

In order to get closer to the price structure of the dampers selected in Dabas, Hungary, at the very beginning, he offered another miniature shock absorber type from ACE, whose catalog values of 41 Nm/cycle are below the initial data. To be on the safe side, he asked ACE to validate the expected maximum overload of the dampers in the event of an emergency stop as part of drop tests carried out in Langenfeld. For this worst-case scenario, he confirmed the established key data of 55 kg door mass being accelerated at a maximum speed of 2 m/s. Accordingly, ACE’s engineers set up the drop test bench and placed the newly selected miniature shock absorbers on a load cell. In the following series of drop tests, the self-adjusting MC225EUMH type miniature shock absorbers not only decelerated the energy, but also withstood the load with unharmed seals and other important components. BIBUS in Hungary as well as the team at Metal 99 were satisfied with the reliable operation and deceleration of the small components. To prevent more destructive interference from very strong travelers harming their sliding door system, Metal 99 added an additional component. This was possible since the competitive pricing of BIBUS allowed the client team to specially manufacture rubber buffers that give extra protection to the end positions and sliding door profiles.

With a wide selection, ACE’s miniature shock absorbers cover energy capacities between 20 Nm/cycle to 136 Nm/cycle and are still very compact to fit in almost every construction.

Norbert Turi from BIBUS is once again convinced about the service and product strength of ACE as their component supplier: "I think that this case shows us very well the safety reserves that ACE's shock absorbers have. In my opinion, it is worth taking a very close look at the catalog data of all suppliers when it comes to their performance. If someone specifies higher data than ACE for comparable diameters of their dampers, then that is what I call a boast. And if anyone doubts that, I would like to ask for an official comparison test." Metal 99 managing director Péter Garajszki is happy to forgo this and is very content together with his team about an all-round safe, sustainable solution from the BIBUS-ACE team.

www.ace-ace.de