Moxa Enables Onboard Data Processing of Condition Monitoring to Improve Train Maintenance

Moxa Partners with IT Consulting Company to Develop First CBM System for South Korean Rail System.

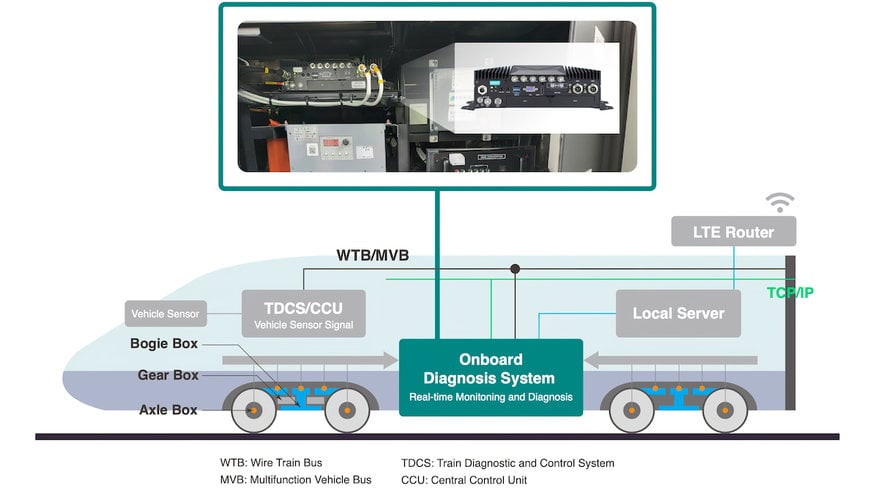

Moxa's computer aids onboard diagnostics while the train is in motion.

In the railway industry, Condition-Based Monitoring (CBM) is a maintenance strategy that uses data from onboard sensors and other sources to monitor the real-time state of railway assets. CBM detects potential issues before they become major problems, allowing for more efficient maintenance and improved passenger safety.

Despite the numerous challenges of setting up a system for continuing, real-time monitoring, Globiz, a South Korean IT consulting firm, saw an opportunity to make a difference in the railway business with CBM. The issue for Globiz was that while the concept behind CBM was valuable on a global scale, its actual application and standards were still in their infancy. As a result, regulation bodies, railway operators, and solution providers like Globiz had to navigate uncharted waters and figure out CBM implementation on their own. Despite these challenges, Globiz successfully developed the first CBM system for South Korea's rail system (KORAIL).

Partnership with Moxa

As with any AI system, preprocessing the data gathered aboard the train is essential for CBM data analysis.

To achieve real-time analysis, Globiz found a partner in Moxa, a world leader in industrial connectivity. Moxa's V2406C Series industrial computer, compliant with global railway EN 50155 standards, performs as the local server to preprocess data collected from onboard sensors and other sources before sending it onto a web server. The onboard diagnostic system powered by Globiz's CBM utilizes Moxa's computer to enable edge computing. Designed for heavy-duty data processing tasks, Moxa V2406C computers are built around an Intel® Core™ i7/i5/i3 or Intel® Celeron® high-performance processor and with up to 32 GB RAM. Additionally, Moxa offered Linux Drivers for the platform.

Moxa V2406C Series Intel® 7th/8th Gen Core™/Celeron® railway computers feature 2 hot-swappable HDD/SSD slots, 2 Mini PCIe expansion slots for wireless, 24 to 110 VDC power input with isolation, and -40 to 70°C operating temperature (click on image to download high-resolution version, image courtesy of Moxa)

JunSik Im, Director/Principal Research Engineer of Globiz commented: “Globiz has found a valuable partner in Moxa, who has provided exceptional local support since the early stages of their collaboration. In previous projects, relying on a computer from a different company meant enduring lengthy support calls to headquarters whenever issues arose. However, with Moxa's local team, Globiz has found a reliable and honest partner for a long-term partnership.”

Moxa assembled a knowledgeable team of local staff and technical experts from headquarters to ensure the partnership with Globiz was successful. This team worked closely with Globiz from the POC stage to the final deployment, addressing issues that arose along the way. Globiz and Moxa built a long-term relationship based on reliability, integrity, and sincerity over two years. Together, they provided technical support to fulfill KORAIL's requirements and complete the Korea Laboratory Accreditation Scheme (KOLAS) verification and Korean Certification (KC).

The CBM project was a significant milestone for Globiz, being the first in South Korea. JunSik Im stated: “Moxa’s extensive product portfolio for railways makes them an ideal partner. We look forward to collaborating with Moxa on future projects.”

Globiz estimates that the benefits of the system in this project include:

- 25-30% reduction in life-cycle costs (LCC)

- 20-30% reduction in spare parts costs

- 40% increase in the lifetime of devices

Because of the success of this project, Globiz has been recognized by Hyundai and train operators and will continue to be a partner to help promote CBM to more cities across Korea.

Moxa offers a range of solutions based on the EN 50155 standard to ensure smooth operations on trains, including wired and wireless devices, computing equipment, and I/O controllers that meet requirements for various onboard systems. Learn more at www.moxa.com/en/solutions/rail.

www.moxa.com