FFG secures major Indian order for turnkey axle production line

MAG IAS GmbH to deliver highly automated system for 60,000 railway axles annually at JTRWF’s new Khurda plant.

www.ffg-asia.com

MAG IAS GmbH (MAG), a member of the Fair Friend Group (FFG), has received a major order to supply a turnkey production line for railway axles from Jupiter Tatravagonka Railwheel Factory Pvt. Ltd. (JTRWF) in India. The highly automated line is designed for the annual production of 60,000 axles and will be installed at JTRWF's new plant in Khurda, Odisha.

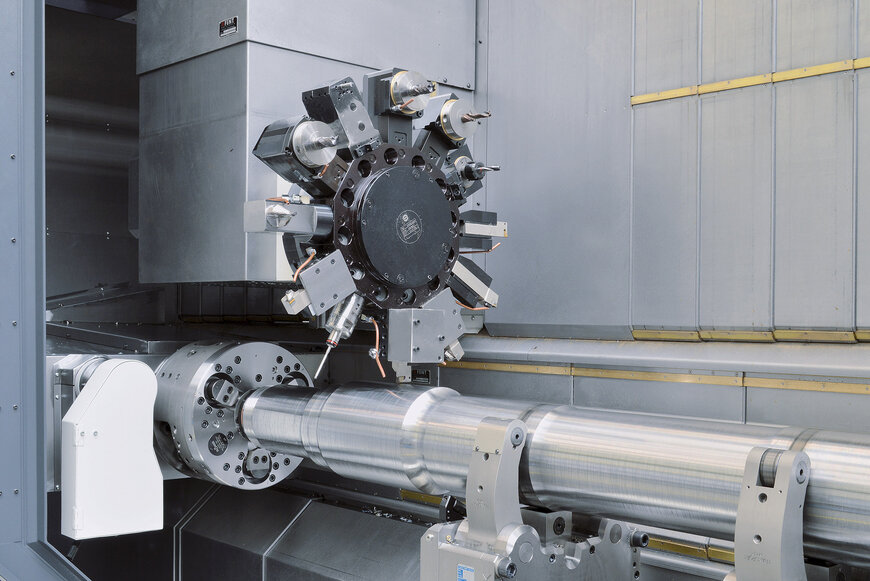

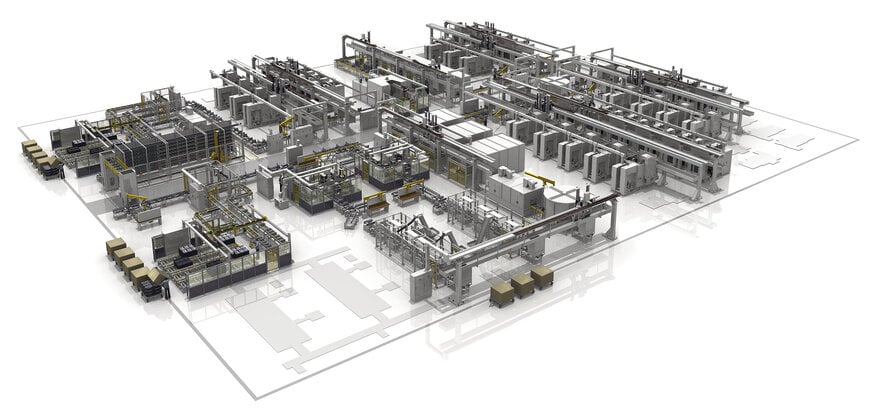

The turnkey solution values in the double-digit million-euros, includes a complete machining and inspection line based on state-of-the-art manufacturing technology. The core of the system consists of high-precision VDF Boehringer VDF 450 4T horizontal turning centers and comprehensive automation solutions, including marking and measuring stations, visual final inspection devices, and a central plant control system with end-to-end system monitoring and component tracking.

Horizontal VDF Boehringer VDF T turning centers enable the economical finishing of railway axles with maximum precision in a single set-up.

“FFG is proud to be part of this pioneering infrastructure project,” explains Dr. Sebastian Schöning, CEO of Fair Friend Group. “Our technological expertise and turnkey solutions make us the ideal partner for JTRWF's local and international goals – both in terms of product quality and sustainability.”

The entire line is designed for high flexibility and energy efficiency. Four different axle types can be manufactured with minimal changeover effort. MAG relies on a digital plant twin and comprehensive 3D simulations for planning, commissioning, and optimization. Pre-calculated energy consumption in various operating scenarios enables resource-efficient manufacturing.

The innovative design of the VDF T series guarantees high productivity at low costs per part and impresses with its reliability, availability, easy maintenance, excellent serviceability, and flexibility.

The implementation will take place in close cooperation with the Indian subsidiary MAG IAS India Industrial Automation Systems Pvt. Ltd. “With the newly established site in Khurda, we are ensuring that JTRWF receives comprehensive technical support of the highest standard,” emphasizes Shashank M.P., Managing Director of MAG IAS India Industrial Automation Systems Pvt. Ltd. “Our team will support our own brand machines as well as provide service for third-party components.”

As a global provider of innovative turnkey solutions, FFG – in particular MAG IAS GmbH – supplies high-quality machine tools and machining centers for the production of electric & combustion engines, crankcases, axles, and wheels for a range of industries.

With this project, MAG once again underscores its role as a leading provider of complex manufacturing systems for the railway industry. The collaboration with JTRWF demonstrates how end-to-end automation, digital planning, and global service expertise can lead to sustainable solutions in international rail vehicle manufacturing. Approximately 50 percent of production capacity is earmarked for export – a clear signal of the project’s international focus and the site’s competitiveness.

Production start in Khurda is planned for the third quarter of 2026. Until then, MAG will support all steps – from final system integration to the qualification of the on-site operating and maintenance teams.

www.ffg-ea.com