railway-international.com

06

'25

Written on Modified on

HARTING Americas Unveils New Products to Drive Smart Factory Innovations

The new solutions include the Han Protect connector, the D-Sub PushPull connector, and Single Pair Ethernet (SPE) technology.

www.harting.com

HARTING, the gold standard in connectivity for industrial environments and mission-critical applications, announced the launch of three new products designed to meet the evolving demands of modern automation systems.

Han® Protect

Han® Protect connector delivers externalized fuse for faster maintenance and compact designs. This innovative solution integrates a fuse directly into the exterior of the control cabinet — simplifying maintenance and saving valuable panel space:

- Rapid Serviceability: Fuses can be replaced in minutes by general technicians, reducing downtime and avoiding costly troubleshooting.

- Improved Safety: External fuse access eliminates the need to open control cabinets, minimizing risk during maintenance.

- Space Optimization: Reduces cabinet size by up to 30% by removing the need for internal fuse blocks.

D-Sub PushPull

D-Sub PushPull connector ensures enhanced industrial connectivity without tools. Based on the industry standard D-Sub interface, the PushPull variant introduces key enhancements for industrial environments:

D-Sub PushPull connector ensures enhanced industrial connectivity without tools. Based on the industry standard D-Sub interface, the PushPull variant introduces key enhancements for industrial environments:

- Quick Connect Mechanism: Slashes installation and service time.

- 360 Degree Unplugging Flexibility: Designed for t-spaces, optimizing ergonomics and accessibility.

- Industrial-Grade Durability: Engineered to perform in harsh and demanding environments.

- Universal Application Compatibility: Backward-compatible with standard D-Sub connectors, making it easy to integrate into existing systems.

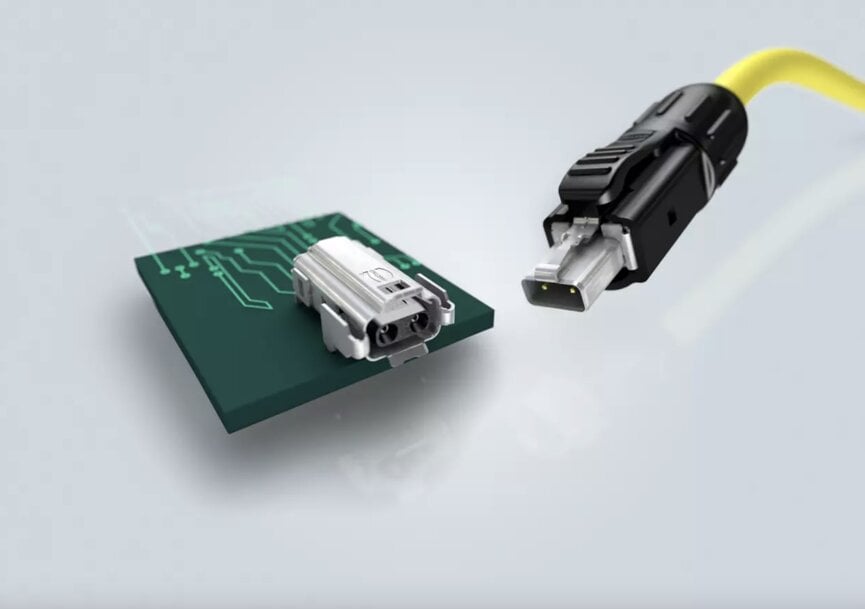

Single Pair Ethernet (SPE) Technology

The Single Pair Ethernet communication solution for locomotives was developed in partnership with some of the biggest North American Class 1 freight railroads in an effort to digitally modernize the locomotive-to-locomotive MU communication network.

The Single Pair Ethernet communication solution for locomotives was developed in partnership with some of the biggest North American Class 1 freight railroads in an effort to digitally modernize the locomotive-to-locomotive MU communication network.

- Cost-effective due to the reduction in copper usage, migrating from 2 or 4 pairs down to just 1 pair.

- Smaller cable size simplifies the Ethernet cabling infrastructure, making installation and maintenance easier while reducing labor costs.

- 50% less weight than traditional 2 or 4 pair Ethernet cable.

- Offers up to 10x greater range and device coverage – supporting 10Mbps at distances up to 1000 meters – with the potential for 10x faster transmission as 1Gbps and multi-gigabit options emerge.