railway-international.com

17

'25

Written on Modified on

ASC Sensors and CETEST elevate testing standards in the transport sector

ASC’s inertial sensor solutions help Spanish test and analysis center CETEST to address critical measuring and evaluation challenges, to provide unrivalled monitoring outcomes to customers across the world.

www.asc-sensors.de

CETEST is an independent technology testing and analysis specialist based in northern Spain, providing advanced engineering, testing and monitoring services. It is accredited according to ISO17025, the principal universal standard ensuring competent quality testing, monitoring and calibration results by laboratories and technology

companies worldwide.

Grounded in railway expertise

Based on a more than 30-year legacy in railway technology evaluation CETEST has been helping leading global rail manufacturers including Alstom, CAF, Hitachi, Siemens or Stadler through the relevant regulatory approval processes for new and refurbished vehicles, individual components and systems around the world.

In 2010, following EN9100 accreditation, CETEST expanded its services to the aeronautics and wind power sectors. To be able to offer customers the most advanced services and push further the boundaries of innovative mobility and sustainable energy testing and certification, the test expert keeps investing in R&D, a highly skilled workforce, the latest state-of-the art technologies and instruments; as well as like-minded partners who offer the same level of professional curiosity and dedication, technical innovation, solution-driven expertise yet also the flexibility to venture into new areas together.

Pantograph optimization at more than 350 km/h

One area in which the Spanish testing lab has developed industry leading expertise is the critical interaction between pantographs and overhead lines. This aspect is key in the validation of new rolling stock to run on existing infrastructure, as well as in approving new infrastructure designs. It also bears a significant impact on maintenance costs.

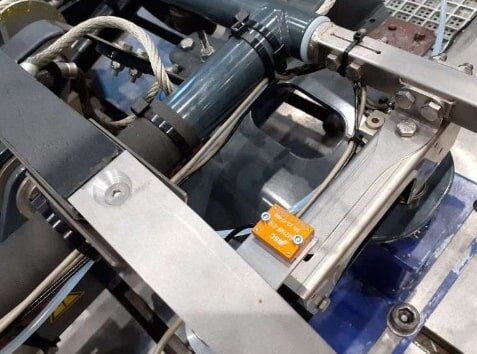

Uniaxial ASC 4421MF accelerometers play a pivotal role at CETEST in evaluating pantograph performance as well as rolling stock ride comfort and dynamic behavior.

Based on proven MEMS technology and capacitive operating principle, they feature a broad measurement range of 2 to 200 g. The integrated electronic circuitry enables a differential analog voltage output (±2.7 V FSO) and flexible power supply voltage from 5 to 40 VDC. ASC’s medium-frequency (MF) accelerometers provide a wide frequency response range of 0 Hz to 7 kHz (±3 dB) and an extremely robust design with shock resistance up to 6,000 g.

“Amongst other applications, we’re using ASC’s accelerometers in a special precision instrumentation system for pantograph contact force testing at train speeds exceeding 350 km/h,” says Carlos Carmuega Tena, Quality Director at CETEST, who has been leading this development. To that end, the ASC MF4421 is employed to measure the vertical acceleration in the pantograph. Based on these measurements, the inertia forces due to effects of the mass of components between the sensors and the contact point get corrected.

Robust sensors resist NVH and electromagnetic interference In these pantograph test series, the sensors are installed between the pantograph body and the contact strip. The latter is in direct contact with the catenary and represents, therefore, a high voltage area.

“Not only does this position lead to high heat exposure to due to the voltages used,” the expert explains. “They also cause plenty of electromagnetic interferences. And the extreme exposure of this demanding sensor application to noise, vibrations and harsh environmental conditions (NVH) like heat, rain and ice plays an even bigger role in obtaining accurate, stable results.”

To resist all of that, the uniaxial ASC 4421MF series features a reliable lightweight aluminum housing of protection class IP67 and an integrated cable of configurable length with connectors. Its ultra-flat design allows for convenient, easy installation, a fundamental requirement in pantograph testing as the position, size and weight of the sensors used are of particular relevance for the validity of the tests results: standard EN50317 establishes limits to the aerodynamic influence, which the measurement system must comply with.

“When we evaluated accelerometers from other manufacturers previously, an issue we encountered was that those were easily damaged by the high voltages,” Carmuega Tena remembers. “Using ASC’s robust sensors, we can now avoid electrical problems due to voltage and obtain good quality signals, despite electromagnetic interferences and other external conditions.”

Ride comfort & dynamic behavior testing

“While our original collaboration with ASC Sensors started because of their accelerometers’ superior measuring behaviors and electromagnetic immunity benefits in our pantograph tests, we soon started exploring additional uses,” reflects the CETEST engineer. “Another decisive advantage was the convenient compatibility of ASC’s sensor technology with our existing instrumentation and measurement data processing ecosystem. Its competitive pricing, delivery times, compact dimensions and ease of installation also turned out to be a great fit.”

Therefore, after rigorous evaluations of various alternative sensor models, CETEST started leveraging the ASC 4421MF accelerometer in dynamic behavior and ride comfort analyses, too. For passenger comfort testing according to ISO2631 and EN12299, the sensors are installed inside the respective vehicle to measure all vertical, lateral and longitudinal movements, obtaining comfort values in each position.

For dynamic behavior tests under EN14363, inertial sensors get installed at various points inside the train as well as bogies and axle boxes externally. “The ASC accelerometers’ broad available measurement range lends itself to this approach,” states Carmuega Tena. With vibration loads and frequencies varying significantly between the different areas and components, CETEST utilizes accelerometers ranging from 2 to 100 g. “Apart from their individual ranges, all other parameters of the ASC 4421MF series remain consistent. Which greatly facilitates both their integration in our measurement system and achieving consistent, valid results.”

Post-approval issue detection & gyroscopes

With these and further sensor applications, some trains evaluated by CETEST carry more than 50 individual accelerometers manufactured by ASC Sensors. “We‘re also using them in brake tests for measuring the acceleration and deceleration of the train. As well as in investigations into specific issues occurring in active trains post approval,” the testing engineer explains. For example, when vibrations in any part of the train become too intense and their root cause needs to be established and fixed, be it a problem in a suspension element, an equipment installed on the vehicle or something else.

However, not only does CETEST utilize accelerometers. For curve radius determination, for example, triaxial ASC 273 gyroscopes of measuring ranges 75 and 150 °/s (available up to 900 °/s) get applied. “National and international railway certification norms require us to conduct several different speed and acceleration analyses, each at various curve radii,” says Carmuega Tena. Combining the train’s speed with accelerometer and gyroscope signals, an algorithm calculates the accurate curve radius that forms the basis of compliant curve behavior analysis. “To get approved for active service, a new train model needs to pass each of these curve tests, at various defined curve radii, speeds and accelerations.”

ASC 273 gyroscopes are based on high-quality MEMS vibrating ring sensor elements. The design of the micro-mechanical silicon structures makes them extremely insensitive to external impacts and vibrations. Therefore, they are ideally suited for use in harsh environmental conditions. Due to their robustness, strong performance and precision they meet industrial grade requirements and are frequently used in dynamic roll, pitch and yaw angle measurements in railway and motor vehicles, ships and aircraft, as well as the monitoring of dynamics and position control of automated guided vehicles (AGVs) and unmanned aerial vehicles (UAVs) in smart agriculture.

Calibration & quartz-based sensor applications

In addition, the MEMS-based uniaxial ASC QF-1211 accelerometer serves as a calibration reference at CETEST, ensuring superior testing accuracy. With their ultralow noise level and a resolution of less than 1 μg, the ASC QF series meets motion class B requirements for seismic monitoring. An in-built self-test ensures the constant

verification of its full functionality. With these characteristics, excellent vibration and shock resistance and their slim design for easy installation, ASC’s QF accelerometers are an excellent choice for capturing the most sensitive amplitudes despite high-vibration environments.

Beyond ASC’s capacitive sensor technology, in 2024 CETEST started leveraging quartz-based accelerometers manufactured by Japan Aviation Electronics Industry, Ltd (JAE), which are available through a collaboration with ASC. CETEST is using JA-40GA accelerometers to evaluate the dynamic behavior of trains while running through curve behavior analyses as detailed above. In these, certification criteria require a train to go through a number of specified curve sections under certain conditions. The measurements must be carried out at the level of the axle-box, where impacts occur with a force of up to 100 g in vertical direction and accelerations of 5 to 10 g in lateral direction. However, the magnitude of the uncompensated lateral acceleration that needs to be measured is even lower and is around 1 m/s2. To overcome this challenge, CETEST employs servo-balanced quartz accelerometers.

“While we used to experience a lot of difficulties with previous suppliers as their sensors proved to be either unstable or not robust enough, JAE’s accelerometers provided and serviced by ASC Sensors turned out to meet our demanding requirements,” states Carmuega Tena. Available for measuring ranges from 2 to 8 g, the JA-40GA series has been developed for low-frequency operations to measure very subtle vibration levels. The signal processing circuit has been optimized to provide ultra-low output noise while maintaining excellent scale factor and bias stability across an operating temperature range from -20 to +70 °C.

ASC 4421MF accelerometer installed at the pantograph (© ASC Sensors)

Mutual partnership to create novel solutions

“As a certified testing laboratory with clients around the globe, we depend on highly accurate and extremely stable sensor equipment to measure exactly what’s required by the respective applicable norms,” says Carmuega Tena. Therefore, factors like sensor dimensions, weight, robustness, frequency response, amplified output and a

choice of diverse measuring ranges – but also short delivery times and competitive pricing – are critical to producing valid outcomes for CETEST’s customers.

“However, beyond the technical quality of their flexible sensor solutions, what’s impressed us over time is the sheer dedication and outcomes orientation of ASC’s engineers. When I ask for a sensor, they ask me for the application. On that basis, they typically come back with tailor-made recommendations for a complete solution addressing our specific challenge. While usually, with other suppliers, we would have to accept a standard product.”

What started with a sensor addressing electrical challenges caused by high voltages and electromagnetic interferences has now progressed to a mutual partnership, where CETEST and ASC Sensors keep creating new sensor solutions together.

www.asc-sensors.de

Mutual partnership to create novel solutions

“As a certified testing laboratory with clients around the globe, we depend on highly accurate and extremely stable sensor equipment to measure exactly what’s required by the respective applicable norms,” says Carmuega Tena. Therefore, factors like sensor dimensions, weight, robustness, frequency response, amplified output and a

choice of diverse measuring ranges – but also short delivery times and competitive pricing – are critical to producing valid outcomes for CETEST’s customers.

“However, beyond the technical quality of their flexible sensor solutions, what’s impressed us over time is the sheer dedication and outcomes orientation of ASC’s engineers. When I ask for a sensor, they ask me for the application. On that basis, they typically come back with tailor-made recommendations for a complete solution addressing our specific challenge. While usually, with other suppliers, we would have to accept a standard product.”

What started with a sensor addressing electrical challenges caused by high voltages and electromagnetic interferences has now progressed to a mutual partnership, where CETEST and ASC Sensors keep creating new sensor solutions together.

www.asc-sensors.de