railway-international.com

16

'24

Written on Modified on

Future-Proof Scroll Compressor in Modern Public Transport

BITZER SPEEDLITE ELV52: Future-Proof Scroll Compressor Ensures Optimal Climate Comfort in Modern Public Transport.

Air conditioning components for rail vehicles for local and long-distance public transport must fulfil a unique set of demands. Space and weight constraints, efficiency, and working life have a direct impact on investment and running costs as well as future compatibility. A decisive factor in this is also the choice of a future-proof refrigerant such as the hydrocarbon propane (R290). The new, ultra-light BITZER SPEEDLITE ELV52 scroll compressor is designed to address all these specific requirements, ensuring a high level of passenger comfort at all times.

© BITZER Kühlmaschinenbau GmbH

Ready for the Future of Rail Transport

As industrial countries worldwide are implementing ever stricter regulations on refrigerants with the EU F-Gas Regulation 517/2014 leading the way, substances with high global warming potential (GWP) are being phased down, becoming scarce and expensive. Furthermore, proposed restrictions on per- and polyfluoroalkyl substances (PFAS) are being drafted through the EU’s REACH chemical regulation. The specialist for refrigeration, air conditioning and heat pump technology BITZER has many years of experience in the field of natural refrigerants, offering a comprehensive portfolio of suitable components. Therefore, the compact, low-noise scroll compressor SPEEDLITE ELV52 for mobile applications was also developed for use with various refrigerants, including low-GWP refrigerants as well as the natural refrigerant propane (R290). As the world continues moving towards more sustainable solutions, the highly flammable hydrocarbon propane is proving to have a promising future in the railway sector. Increasingly more transport companies, for instance, already explicitly require the use of natural refrigerants for the vehicles in their urban areas. Propane is an attractive option due to its excellent thermodynamic properties and low environmental impact. It boils at −42°C and can cover evaporating temperatures of −40°C and higher. Large temperature strokes are easily possible when compressing with this substance.

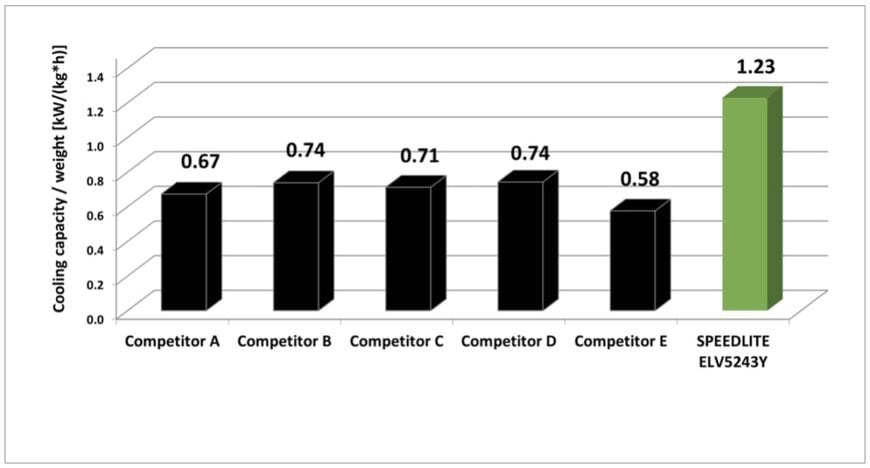

Optimal Cooling Capacity to Weight Ratio

Furthermore, the BITZER SPEEDLITE ELV52 is around 50 per cent lighter than conventional compressors and features a highly efficient suction gas-cooled permanent magnet motor. Lightweight air conditioning systems ensure a reduced roof load, lowering power consumption during operation. As shown in the graphics, the scroll compressor has an outstanding cooling capacity to weight ratio. The SPEEDLITE ELV52 offers 66 per cent more cooling capacity per kilogram than typical scroll compressors in railway vehicles.

© BITZER Kühlmaschinenbau GmbH

Even under drastically changing operating conditions, the compressor demonstrates its efficiency due to its wide control range. Furthermore, a separate speed control adjusts its cooling capacity to the current cooling and heating load. This increases not only the efficiency of the SPEEDLITE ELV52, but also of the whole system, ensuring a stable temperature regulation inside the train – for maximum passenger comfort. Moreover, an integrated Economiser technology expands the application limits of the compressor significantly. The increase in efficiency thanks to the Economiser technology is particularly advantageous in heat pump operation, which is also possible with the SPEEDLITE ELV52. Compared to electric heating systems, heat pumps achieve much higher efficiency, further reduce operating costs and help to meet the requirements of global environmental regulations. Therefore, they will also be at home in the modern rail vehicles of the future.

www.bitzer.de