Digital Automatic Coupler milestone: Knorr-Bremse tests innovative electric contact coupler

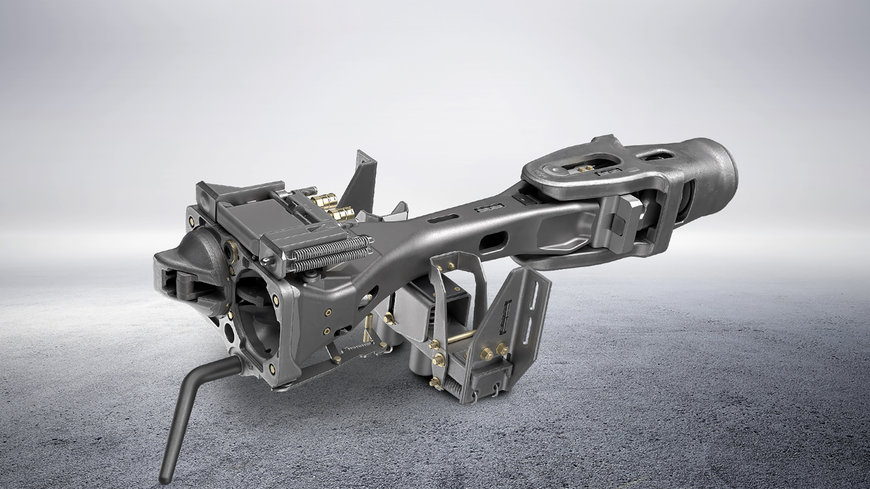

Knorr-Bremse has developed a new electric contact coupler (e-coupler) for the Digital Automatic Coupler (DAC). By connecting power and data lines from the locomotive all the way to the last freight car, e-couplers act as a crucial interface in the digital freight train.

The electric contact coupler was regarded as an exceptionally challenging step in the development of the DAC. Knorr-Bremse has come up with an ingenious solution.

- Knorr-Bremse has taken a decisive step forward in the development of automated system solutions for digital freight transportation

- As a central component of the DAC, the new electric contact coupler will support end-to-end power and data lines on freight trains

- With the e-coupler, Knorr-Bremse is bringing multiple smart functions to the rail freight sector, such as automated brake testing and condition-based maintenance

- The Knorr-Bremse e-coupler is the first such solution to meet all functional requirements within the specified installation parameters – making a major contribution to the DAC rollout across Europe’s rail freight sector

- Knorr-Bremse is committed to ensuring that this solution becomes the manufacturer-independent blueprint for the new industry standard

As such, they are essential for the digitized, intelligent, competitive transportation of freight by rail. For the first time, Knorr- Bremse will be showing the e-coupler as a real exhibit at InnoTrans 2022.

According to Dr. Nicolas Lange, Chairman of the Management Board of Knorr-Bremse Systeme für Schienenfahrzeuge GmbH and responsible for the company’s development activities: “The Digital Automatic Coupler or DAC is regarded as the gateway to the future of automated rail freight – and the electric contact coupler is one of the key modules. Because of the extremely high demands on this component, none of the industry concepts produced so far have been convincing enough. Which is why we’re so pleased that with our systems expertise and strong developer credentials, we’ve been able to find a very promising way to overcome this challenge. Our e-coupler breakthrough should make a major contribution to helping the industry meet the agreed timelines for the Europe-wide DAC rollout.”

Robust, sophisticated e-coupler design meets highly demanding specification

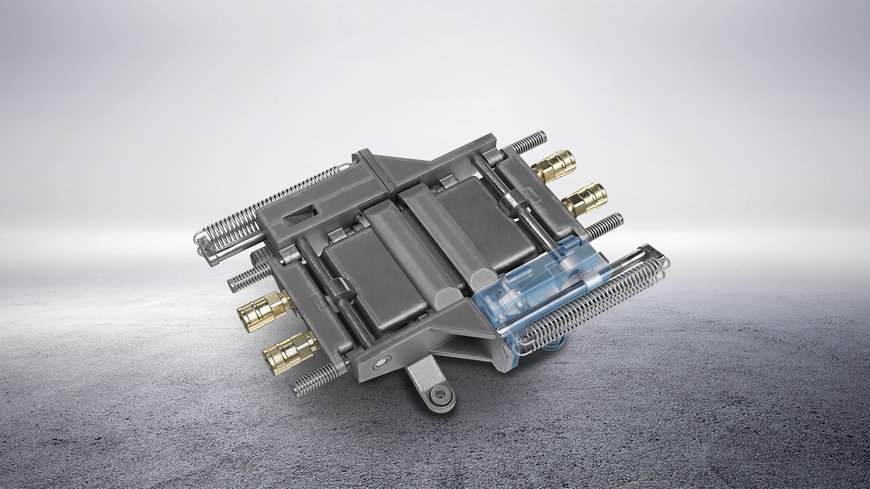

The Knorr-Bremse e-coupler is the first concept to satisfy all the requirements of the European DAC Delivery Programme (EDDP) specification used as the framework for coordinating the Europe-wide launch of the DAC. They include, among other things, very restricted dimensions, high weathering resistance, and the ability to establish a connection between the delicate electrical contacts on two freight cars safely and gently during the coupling process. With respect to dimensions: Together, the DAC plus mounted e-coupler are not supposed to extend more than 200mm from the center of the coupler head. This is the only way to ensure that when loading, for example, new vehicles onto a train, the vehicles are able to drive smoothly over ramps laid between one freight car and the next.

Despite these constraints, Knorr-Bremse’s innovative solution is based on a sophisticated but robust mechanical principle. Nils Möhle, Director of Coupler Development at Knorr- Bremse Rail Vehicle Systems, explains: “Shifting from a fixed to a movable version of the e- coupler turned out to be a crucial step in the development process. This approach meant we could minimize its overall height and make it less susceptible to wear, because the electrical contact block retracts during the mechanical coupling process and then closes the electrical connection by engaging with its counterpart in a very controlled way.” An additional cover protects the e-coupler from goods accidentally falling from above.

E-coupler design to become an industry standard

Knorr-Bremse is supporting that this concept will act as a blueprint for the EU-wide e-coupler specification, and consequently become the mass production and market rollout standard for all DAC manufacturers. With this in mind, Knorr-Bremse has submitted the design to the Europe’s Rail Joint Undertaking (ERJU), which is tasked with preparing an interoperable DAC that will be compatible with the fleets of all EU-based operators for series production. Knorr- Bremse will also subject the e-coupler design to intensive testing in the company’s coupler test facility in Budapest, with the aim of optimizing it even further.

Knorr-Bremse intends to become a leading supplier of automated system solutions for freight transportation by 2026. By leveraging the company’s engineering skills, industrialization expertise and close-knit service network, backed by a systems approach based on high- quality hardware (DAC), its own automation system and data-driven services, Knorr-Bremse aims to add substantial value to rail freight operations.

At present, around 500,000 freight cars and 17,000 locomotives are still coupled by human labor, for the most part manually. This means that the rail freight sector represents a vast future market for automation and digitalization. The aim is to shift a significant proportion of the freight currently still transported by truck over to green rail by 2030. But to meet this ambitious target, rail freight must become much more efficient and flexible – by adopting innovations like the DAC.

www.knorr-bremse.com