railway-international.com

13

'22

Written on Modified on

Technologies for increasing the capacity of railway infrastructure

The 13th edition of InnoTrans, the world's leading trade fair for transport technology, is almost fully booked. Plasser & Theurer will once again be among the exhibitors in the railway infrastructure sector.

After the convincing performance at iaf in Münster under the motto "future track technology - NOW", the company will also present innovations in Berlin that clearly show that it understands which topics will determine the future of the industry.

Rail is the most environmentally friendly transport system. A fact that cannot be emphasised enough, especially in times of climate change. In this respect, technologies that make this system even more economical, efficient, and sustainable are all the more in demand today. As a global technology leader in track construction and maintenance, the Austrian family-owned company makes a significant contribution to these goals. In Berlin it will come up with innovations that open up new paths into the future once again, addressing the topics of digitalisation, greening, and automation.

Largest single order in the company's history

Even in the run-up to InnoTrans, Plasser & Theurer was able to chalk up a success that was made possible by innovations of precisely this kind. At the end of a two-stage EU-wide tendering process, ÖBB-Infrastruktur awarded the company the contract for 56 zero-emission high-performance maintenance vehicles (21 Plasser MultiCrafters, 29 Plasser CatenaryCrafters for the overhead contact line, and six Plasser TransportUnits) worth almost €250 million. A purchase option is available for an additional 46 vehicles. The E³ drive technology, which enables an environmentally friendly electric hybrid drive, convinced them. It was also crucial that the vehicles are fit for future technologies, such as the ETCS train control system.

Johannes Max-Theurer – Plasser & Theurer, CEO: "Orders like this prove that with our machines we not only promote economical track maintenance, but also sustainably achieve the climate goals of the rail transport system with the innovative, environmentally friendly drive and work technology."

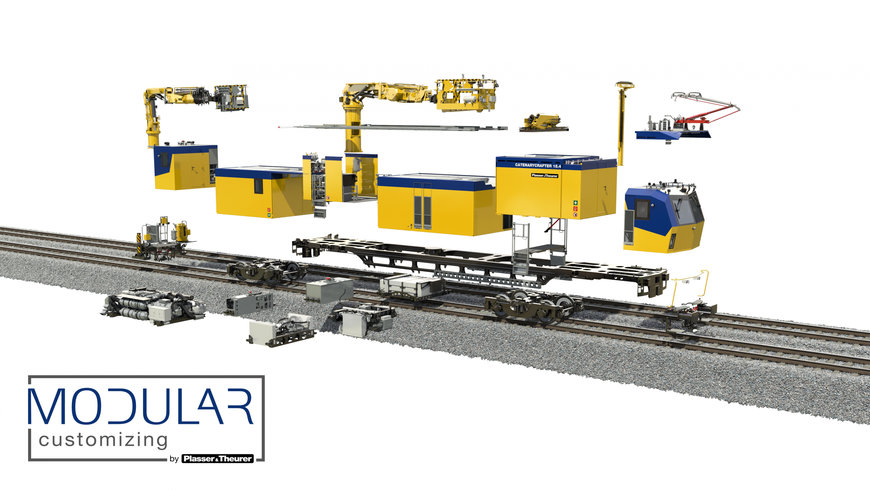

Shorter delivery times and lower costs with ModularCustomizing

Not to be underestimated in winning this largest single order in the company's history was the ModularCustomizing concept, on the basis of which the vehicles are designed and manufactured. The development of the concept began about 10 years ago with the construction of 48 maintenance vehicles for Deutsche Bahn and has been consistently pursued ever since. Today, different machines can be built from modules with a 100 % level of detail and precisely defined interfaces in less time and at lower costs. The advantages of this design become effective over the entire life cycle of the machines, as it not only significantly facilitates maintenance, but also repairs and refurbishments.

A highlight of Plasser & Theurer's current product range will be presented in the outdoor area of InnoTrans: the Unimat 09-4x4/4S Dynamic E³ with the revolutionary E³ hybrid technology. This universal tamping machine is the first hybrid machine for DB Bahnbau Gruppe GmbH (a Deutsche Bahn AG company), which is equipping itself to meet a number of current challenges in the areas of climate protection, occupational safety, urban working operations, and the reduction of equipment and resources.

In addition to the conventional drive system, the machine can be fully electrically powered during running and working mode. All rotary motions are powered fully electrically. Only a few linear motions remain hydraulically powered. The drive technology reduces hydraulic oil consumption by 80 %. Running mode using carbon-neutral traction current lowers diesel consumption drastically. Additionally, E³ reduces noise emissions significantly and thus increases line-side residents' acceptance of the machine.

A speed-up for spare and wear parts

Over the past two years, Plasser & Theurer’s Customer Services division has developed very dynamically. The focus is always on meeting customer and market requirements in a professional and sustainable manner. Life cycle enhancement, eco-retrofitting, and used machines can serve as examples in this context.

The European Distribution Center in Linz will start test operation in the summer of 2022. This is the beginning of a new era for Plasser & Theurer spare and wear parts provision. The goal is to have all frequently ordered parts in stock and to enhance customer satisfaction with shorter delivery times. An improved supply chain is key to reducing delivery times and optimising parts costs.

Machine, fleet, and infrastructure remain at the top of the agenda

Plasser & Theurer is dedicated to providing precise answers to current market needs with new technologies. In addition, the Austrian technology leader remains true to its objectives in the machine, fleet, and infrastructure segments. In the machine segment, ModularCustomizing is a new offer that provides an individualised fleet with high standards. In the fleet segment, the focus remains on services over the entire machine life cycle. In terms of infrastructure, digital solutions for maintaining railway infrastructure and complementary services continue to be the main topics of interest.

The bottom line is that Plasser & Theurer’s aim continues to be innovative contributions that strengthen rail as the most environmentally friendly transport system. Enhancing the capacity of this transport system is becoming increasingly important for the sustainable mobility of the future.

www.plassertheurer.com