THE FUTURE OF RAIL FREIGHT: KNORR-BREMSE DEVELOPS DIGITAL AUTOMATIC COUPLER

Knorr-Bremse is developing a portfolio of couplers for making rail transportation even more efficient and flexible. With respect to the Digital Automatic Coupler (DAC) for freight trains, the company is concentrating its resources on producing the first prototypes, which will then be optimized for series production by the start of the planned upgrade phase mid-decade.

Knorr-Bremse is hard at work developing a Digital Automatic Coupler for the rail freight industry; this is

the company's latest DAC design. | © Knorr-Bremse

- After building the first prototypes in 2022, Knorr-Bremse will focus on testing them in pilot projects and preparing for high-volume industrialization to help satisfy the high market demand for couplers

- As soon as retrofitting of the up to 500,000 freight cars in the EU starts from the second half of the decade, Knorr-Bremse sees itself in a position to become a leading DAC supplier

- The DAC is a key element in Knorr-Bremse’s end-to-end system for automating and digitalizing rail freight traffic

- In parallel, Knorr-Bremse is working on expanding its portfolio of passenger train couplers to boost the market launch with a broad range of offerings

As for Knorr-Bremse’s portfolio of couplers for passenger trains, the company is at an advanced stage of validation, expanding the range of modular options and ramping up production facilities.

Dr. Jürgen Wilder, Member of the Executive Board of Knorr-Bremse AG and responsible for the Rail Vehicle Systems division, lays out the situation as follows: “Based on tonnes per kilometer, rail is the mode of transportation with the lowest carbon emissions. But to build the backbone of an environmentally friendly freight-handling system and become competitive with other modes of transportation, it is essential to invest in new technologies and roll them out across the industry. We regard the Digital Automatic Coupler as a key lever for bringing rail freight into the digital age. If the political will to support this huge project continues, and the process of upgrading freight cars is kicked off in the second half of this decade, we believe we’ll be in a position to become a leading supplier of DACs and many other automation systems for the rail freight industry.”

Knorr-Bremse is developing the DAC according to the timeline envisaged in the European DAC Delivery Program (EDDP). The roadmap from initial prototype to the planned full-scale upgrade of as many as 500,000 freight cars and some 17,000 locomotives throughout Europe is regarded as exceptionally challenging. The recent EU-wide decision to opt for a Scharfenberg coupling system, however, has again validated Knorr-Bremse’s development strategy: “Our in-depth engineering know-how, longstanding commercial relationships with manufacturers and operators, manufacturing expertise, and network of local service centers all form a solid basis for successfully bringing our DAC to market and rolling it out,” confirms Dr. Nicolas Lange, Chairman of the Management Board of Knorr-Bremse Rail Vehicle Systems. “Provided the relevant conditions continue to improve at the present rate, we believe there’s a realistic chance of completing this ambitious migration to DAC by 2030.”

Digital couplers: paving the way for digitizing other freight train functions

Knorr-Bremse is designing the DAC to act as the centerpiece of what will, in the future, be a fully digitized freight train. At present, freight cars and locomotives are always coupled together manually; apart from mechanical couplers, the only other link between them is the pipe carrying compressed air for the braking systems. The DAC, on the other hand, will house an air line together with data and power lines supplying the entire freight train – a world first. This means that in addition to supplying DACs for freight cars and hybrid DACs for locomotives, Knorr-Bremse will be able to offer a package of innovative automation options for digital freight trains. An electropneumatic (EP) braking system, automatic brake testing, data and communication services, a smart energy management system, condition-based maintenance (CBM) and cybersecurity are among the many future applications which operators could choose based on their needs.

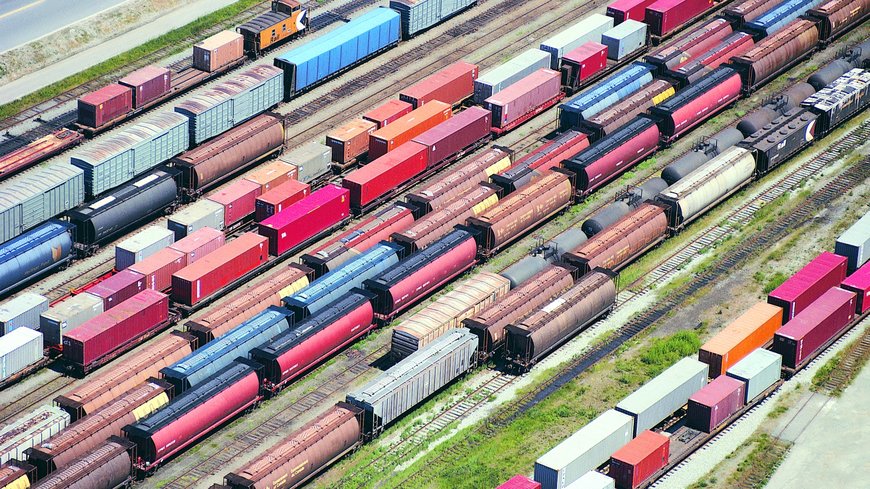

Knorr-Bremse is designing the DAC to act as the centerpiece of a fully digitized freight train – not least to

streamline train-handling processes. | © Getty/Digital Vision.

Given the company’s technological expertise and experience of industrialization, Knorr-Bremse believes it is in a perfect position to make a significant contribution to satisfying the high market demand for couplers. At the same time, a joint effort by the entire rail sector is required to ensure the success of the DAC rollout. Consequently, as a member of EDDP and Shift2Rail, Knorr-Bremse is working with other companies to drive forward the DAC rollout across Europe. European manufacturers and operators are agreeing joint specifications and migration strategies, and DAC prototypes from individual players have already been tested in the field as part of EDDP’s DAC4EU project. Based on this work, a recent decision was made to adopt a Scharfenberg-type coupler, one of four test variants. Knorr-Bremse’s DAC is already equivalent to this type of coupler.

In addition to its transformative benefits for rail freight, such as streamlining the efficiency of train assembly and dispatching processes, the universal rollout of DAC represents an acceleration of the campaign to equip freight train fleets with digital automation systems. It is precisely the interaction of automated trains with the European Train Control System (ETCS) (installed on the locomotives) and track infrastructure that will help increase capacity across the entire rail network, making it possible to sustainably transport even larger quantities of freight. Only by combining all these efficiency initiatives will it be possible to meet the EU’s target: to transport 30 percent of all freight by rail by 2030.

www.knorr-bremse.com