railway-international.com

02

'20

Written on Modified on

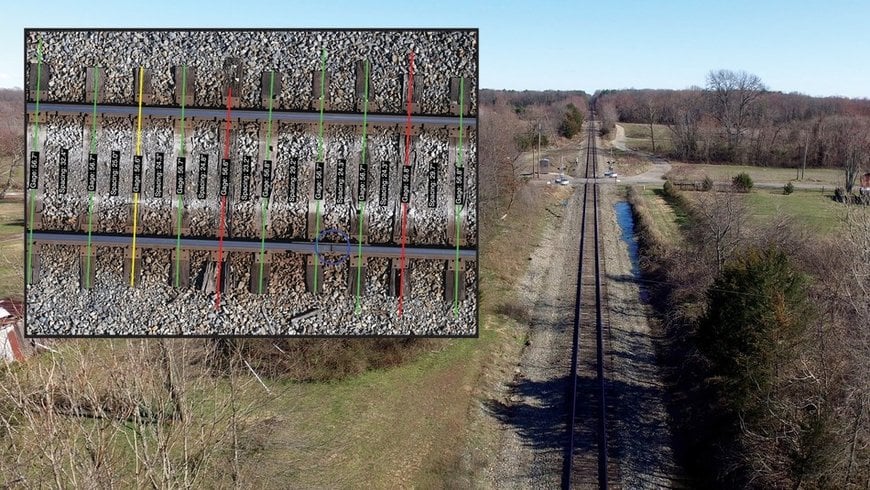

Ardenna introduces Rail-Inspector, the most advanced inspection and track health software for railroads and industrial rail asset owners

Automatically generates comprehensive, objective and quantifiable track condition data from aerial imagery, enabling data-driven maintenance decisions that reduce costs and improve worker and railroad safety.

Ardenna announced today the general availability of Rail-Inspector, its cloud-based software that accurately processes and analyzes imagery captured during drone surveys. Rail-Inspector identifies and measures railway features, classifying anomalies and determining the health of railway features, while reporting on areas of concern to railroad decision makers. Some of the track features identified include crossties and their condition, joint bars, fasteners, frogs and switches. Track features measured include rail gage and gaps, tie spacing, tie angle, percent ballast covering ties, and more.

Drone surveys remove the need for possessions and line blocks, ensuring significant cost savings. The breadth of information Rail-Inspector reports from an individual drone survey augments a typical human inspection and simultaneously provides a level of insight into the track health only available using costlier solutions. Track owners benefit from a reduction in maintenance downtime, increased operational efficiency, and improved worker and railroad safety -- all while providing a visual and digital record of rail assets. Once multiple drone surveys have been performed, track health trends can be identified, leading to predictive track maintenance.

"Every business is looking for ways to obtain more insight into the health of their assets without impacting worker safety or operational efficiencies. Imagery from drone surveys satisfy those requirements," said David M. Patterson, Business Development Director for Ardenna. "Rail-Inspector takes those images, whether 10 or 10,000, and generates a comprehensive dataset, representing details associated with the track's current health that would be impractical to obtain using other methods. By watching these track details evolve over time, trends can be identified, enabling maintenance to be scheduled and performed proactively before human or rail safety is impacted."

Track imagery, successfully processed by Rail-Inspector, has been collected from numerous drone platforms (DJI Phantom 4, DJI Mavic 2 Enterprise, DJI M600 and Latitude HQ-60) and camera payloads (12 MP, 20 MP, 29 MP, 60 MP and 100 MP). Rail-Inspector has also demonstrated the ability to process imagery captured from a manned aircraft and a helicopter. A future configuration will have the imagery captured from an operational rail vehicle.

www.ardenna.com