SAFE AND COMFORTABLE MOBILITY: HOW KNORR-BREMSE IS HELPING OPERATORS TO REVIVE RAIL TRANSPORT AMIDST COVID-19

As half-empty trains have unfortunately become a common scene in countries around the world during the Covid-19 pandemic, Knorr-Bremse, the global market leader for braking and other systems for rail and commercial vehicles, is actively supporting railway operators worldwide to bolster health and comfort in rail transport.

Knorr-Bremse is actively supporting rail operators worldwide in providing safe and comfortable rail transportation during the Covid-19 pandemic.

- Knorr-Bremse is actively supporting rail operators worldwide in providing safe and comfortable rail transportation during the Covid-19 pandemic

- Knorr-Bremse’s heating, ventilation and air conditioning systems (HVAC), including solutions for air distribution, active and passive filtering and purification, are contributing to cleaner in-train air

- Knorr-Bremse is making a key contribution to rebuild trust in public transport and help normalize its widespread use

With its unparalleled clean[air] technology, developed by Knorr-Bremse’s climate control brand MERAK, air quality can be rapidly restored and any airborne concentration of aerosols and pathogens drastically reduced.

“As a leading systems innovator for heating, ventilation and air conditioning technology, it is within our best interest to assist rail operators worldwide in restoring normality in the use of public transport and reactivating mobility by rail,” says Dr. Jürgen Wilder, Member of the Executive Board of Knorr-Bremse and responsible for its Rail Division.

“Providing state-of-the-art solutions for air distribution, active and passive filtering and purification, as well as systems know-how, we have mobilized a dedicated, distributed and multi-disciplinary team to support our partners,” adds Dr. Peter Radina, Member of the Management Board of Knorr-Bremse and also responsible for the HVAC business of Knorr-Bremse Rail Vehicle Systems.

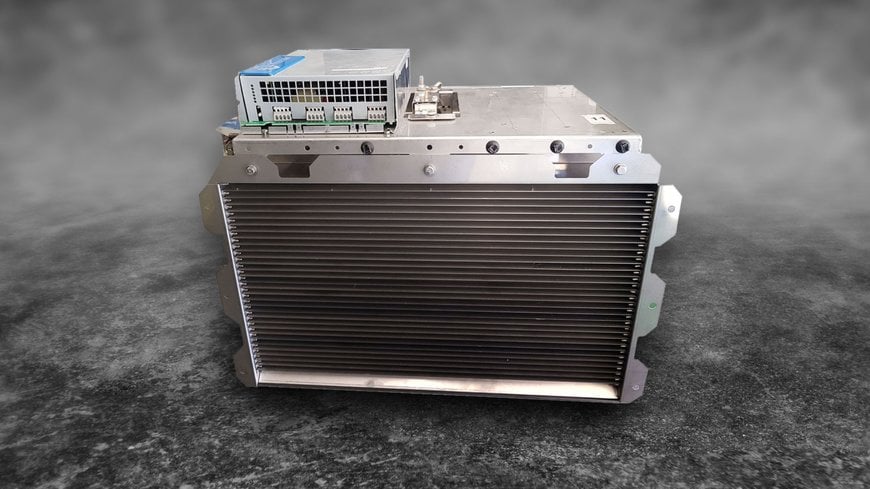

UV-C lamp for HVAC systems for rail vehicles.

clean[air] has been developed over decades of rail climate control practice. It basically acts in three dimensions that can be deployed in a customized multi-layer strategy to combine short-term effectivity with sustainable long-term action:

Optimized air distribution: MERAK systems feature aerolic architectures that maximize comfort while minimizing transversal airflow through the passenger compartment (e.g. for Italy’s high-speed fleet since 2014). The systems prioritize vertical patterns, i.e. air injection from compartment ceilings and air suction from compartment floors, as well as air renewal in periods demanding sanitation.

Long-life passive and near-field active filters: MERAK systems are equipped with multi-stage filtering systems that can be easily fitted into existing trains and are able to arrest all particle sizes below 30 micrometers (µm) with efficiencies of up to 99% – a level similar to high efficiency filters, but without the detrimental pressure drop and energy consumption, as already tested on several Metro and high-speed applications, e.g. in Asia.

Air purifiers: MERAK systems feature UV-C lamps, first deployed on high-speed trains in Russia in 2009 and later expanded to commuter trains in 2015, e.g. in Belarus, and the more recently developed plasma technology, enabling the destruction of residual microorganisms. As early as 2007, tests were conducted with bacteria and corona-type viruses, achieving >90% sanitization after only 30 seconds of exposure and complete absence of bacterial activity on filter surfaces within less than 30 minutes, thus providing enhanced safety for passengers and rail staff.

MERAK not only provides clean[air] products, but complete system solutions, validated in its dedicated air quality lab. They can be adapted to the specific requirements of each rail transportation mode, e.g. different average travel and interstation distances, standing or seated passenger density, single- or multi-level vehicles and even sleeper cars. Today, MERAK’s systems are customized to clients’ needs all over the world, thanks in part to Knorr-Bremse’s unique global engineering expertise, production network and service presence.

www.knorr-bremse.com