Polyurethane vs. Traditional Insulated Joint Materials: Cost, Lifecycle, and Performance

Discover how modern polyurethane insulated rail joints outperform traditional epoxy systems, delivering longer service life, reduced maintenance, and improved reliability for today’s high-demand rail networks.

www.cometind.com

The Hidden Hero of Track Integrity

In the vast network of global railways, a small but critical component maintains safety and efficiency: the insulated rail joint (IRJ). Often unseen, these joints are the hidden heroes of track integrity, providing electrical isolation between rail sections. This isolation is essential for the functioning of track circuits and signaling systems, ensuring rail signal integrity and allowing operators to safely and accurately detect train position.

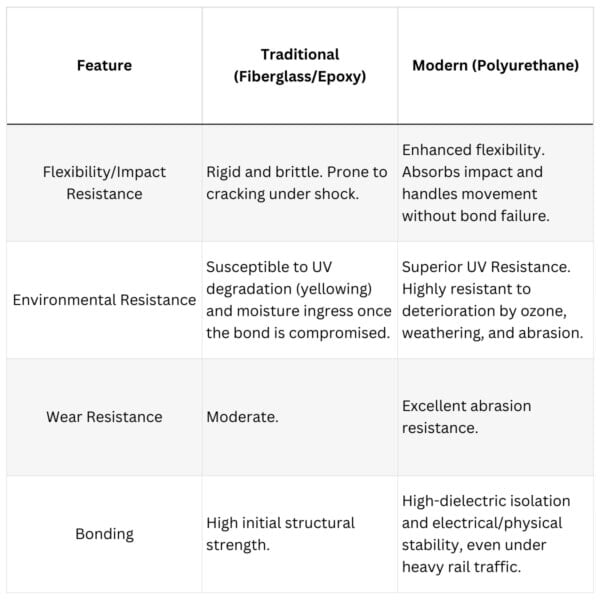

The material composition of the joint, whether it is made from older fiberglass, traditional epoxy, or modern polyurethane, directly impacts its performance and longevity. As rail networks worldwide modernize and face increasing traffic demands, polyurethane joint bars have emerged as the preferred choice for operators seeking longer service life and lower maintenance requirements.

Understanding Insulated Joint Bars

Insulated rail joints are essential for dividing the track into discrete electrical blocks. This segmentation is fundamental to track circuit isolation, allowing the signaling system to monitor which sections are occupied by a train. The basic rail joint assembly typically includes two insulated joint bars, an insulating end post between the rail ends, and insulated bolts and bushings designed to prevent current leakage between the components.

The choice of the insulation material is the single most important factor determining how well the joint will withstand the crushing dynamic loads, immense shear stresses, and varying environmental conditions that railway tracks endure.

Traditional Materials: Fiberglass and Epoxy-Based Systems

Historically, fiberglass-reinforced epoxy and bonded steel joints were the standard for both high-tonnage freight and metropolitan transit applications. While providing adequate electrical insulation initially, these traditional IRJ failure modes are well-documented:

Epoxy Debonding: The primary mechanical failure mode is the debonding of the epoxy adhesive from the rail and joint bars. This process typically begins near the end post (the center of the joint) and grows outward. As the debonding progresses, the joint loses its structural stiffness, becoming weaker and allowing for greater deflection under load.

Brittleness: Epoxy’s inherent rigidity and lack of flexibility mean that it can crack under the constant vibration, stress cycles, and thermal shock experienced in a dynamic rail environment.

Mechanical and Electrical Failure: Once the bond is sufficiently weakened, moisture can penetrate the joint, leading to corrosion. This ultimately results in mechanical failure due to excessive wear, broken bolts, and joint bar cracks, and electrical failure, where metal surfaces come into contact. A common cause of electrical failure is rail end batter, where the ends of the rails “lip” over and make electrical contact.

The combined effect of these failures drastically shortens the joint’s service life, leading to high maintenance cost comparison and unplanned track downtime.

The Polyurethane Advantage

Polyurethane represents a significant leap in rail material science, specifically engineered to overcome the weaknesses of traditional epoxy systems. While epoxy generally offers a higher initial tensile bond strength, polyurethane excels in the properties that are most crucial for longevity in a dynamic rail environment. The advantages are clear:

Polyurethane is a specifically formulated compound that resists the shock and flexing stress of heavy axle loads, providing vastly superior rail joint durability. Its inherent flexibility prevents the micro-cracking and debonding that plagues brittle epoxy joints, ensuring the insulating layer remains intact and protected.

Cost and Lifecycle Comparison

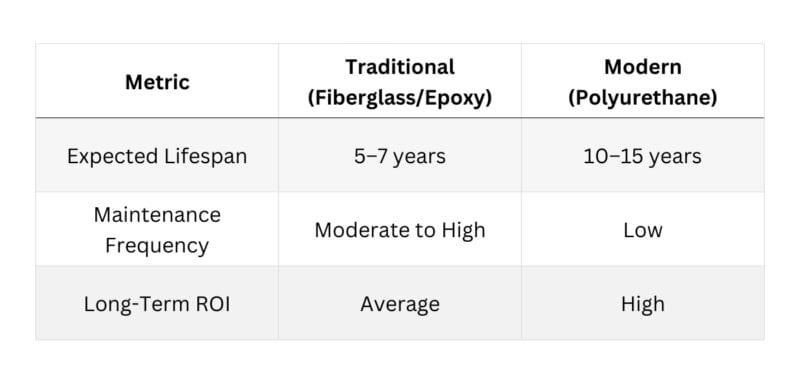

When evaluating infrastructure components, the total cost of ownership (TCO) is far more telling than the initial purchase price. While polyurethane joints may cost more initially, the return on investment (ROI) perspective is compelling.

The extended insulated joint longevity of polyurethane-based systems, often double that of traditional joints, is the primary driver of a high polyurethane ROI. By reducing the frequency of replacement by 50% or more, operators realize significant savings in labor, material, and critical track downtime. On high-tonnage routes where IRJs made with traditional materials may need replacement in as little as 12 to 18 months, the switch to advanced materials ensures the rail joint lifecycle is economically viable and supports consistent, reliable operations.

Performance in the Field

Polyurethane IRJs are now considered field-tested rail joints and have demonstrated reliable performance in the most demanding conditions. Their superior resilience to vibration and load cycles minimizes failures in busy rail corridors, ensuring consistent high-traffic rail performance.

They are particularly suited for environments with high moisture, freeze-thaw cycles, or chemical exposure, establishing them as a robust weather-resistant rail joint. Furthermore, their mechanical stability ensures proven compatibility with modern signaling systems and AEI-equipped (Automatic Equipment Identification) tracks.

Future Trends in Joint Material Technology

The rail industry’s future is moving toward greater track stability, lower TCO, and predictive maintenance. Polyurethane innovation and the use of next-generation rail technology polymers are central to this evolution.

Ongoing research and development is focused on pushing insulation performance even higher, with next-generation polyurethane blends aiming to improve thermal stability. While alternative technologies like continuous welded rail (CWR) systems reduce the need for certain traditional joints, IRJs will remain necessary for track circuit segmentation. Therefore, the future of insulated joints lies in highly resilient materials. As the industry prioritizes lifecycle cost savings and reliability, advanced polyurethane-based systems are expected to dominate new installations and replacements well into the next decade.

FAQs

What is an insulated rail joint (IRJ)?

An insulated rail joint (IRJ) is a specialized connection between two rail sections designed to provide electrical isolation. This isolation enables track circuits and signaling systems to accurately detect train location and ensure safe rail operations.

Why are insulated rail joints important for signaling systems?

IRJs divide the track into electrically discrete blocks, allowing signaling systems to determine whether a section is occupied by a train. Without proper isolation, track circuits cannot function reliably.

What causes traditional fiberglass or epoxy-based IRJs to fail?

Common failure modes include epoxy debonding, brittleness, moisture ingress, corrosion, broken bolts, joint bar cracks, and electrical failure from rail end batter. These issues reduce structural strength and shorten service life.

How does polyurethane improve IRJ performance?

Polyurethane offers enhanced flexibility, superior impact absorption, excellent UV and environmental resistance, and high-dielectric isolation. These properties reduce cracking, prevent debonding, and extend the joint’s usable lifespan.

What is the expected lifespan of polyurethane IRJs compared to traditional joints?

Traditional fiberglass or epoxy joints typically last 5–7 years, while polyurethane-based joints usually last 10–15 years—often doubling the service life.

How does polyurethane reduce total cost of ownership (TCO)?

Because polyurethane IRJs last longer and require fewer replacements, operators save significantly on labor, materials, and track downtime. This results in a higher long-term return on investment (ROI).

Are polyurethane IRJs suitable for heavy-tonnage or high-traffic rail lines?

Yes. Polyurethane IRJs are field-tested and proven to perform reliably under heavy axle loads, frequent vibration, and demanding load cycles found in busy freight and transit corridors.

How do environmental conditions affect IRJ performance?

Traditional epoxy systems are vulnerable to UV exposure, thermal cycling, moisture ingress, and chemical exposure. Polyurethane’s superior environmental resistance makes it more durable in harsh climates, wet environments, and freeze-thaw regions.

Will insulated rail joints still be needed as rail networks adopt technologies like continuous welded rail (CWR)

Yes. Even with advancements like CWR, IRJs remain essential for track circuit segmentation. Future innovations will focus on improving insulation materials rather than eliminating IRJs.

What trends are shaping the future of IRJ materials?

The industry is moving toward advanced polyurethane-based polymers that offer higher thermal stability, extended service life, and lower lifecycle costs. Predictive maintenance and improved insulation technologies will drive next-generation designs.

www.cometind.com