Upgraded Mechanical Design Of Dellner DAC Gen. 4

The Digital Automatic Coupler (DAC) is redefining the rail freight industry, replacing traditional screw couplings with a fully automated solution.

www.dellner.com

By streamlining train formation, boosting safety and enabling real-time data exchange across wagons, DAC is the backbone of tomorrow’s digital freight operations. Dellner is reinforcing its leadership in innovation with the launch of its enhanced Generation 4 DAC with mechanical components. Built for maximum durability, performance and simplified installation, the latest upgrades are fully aligned with European DAC standards.

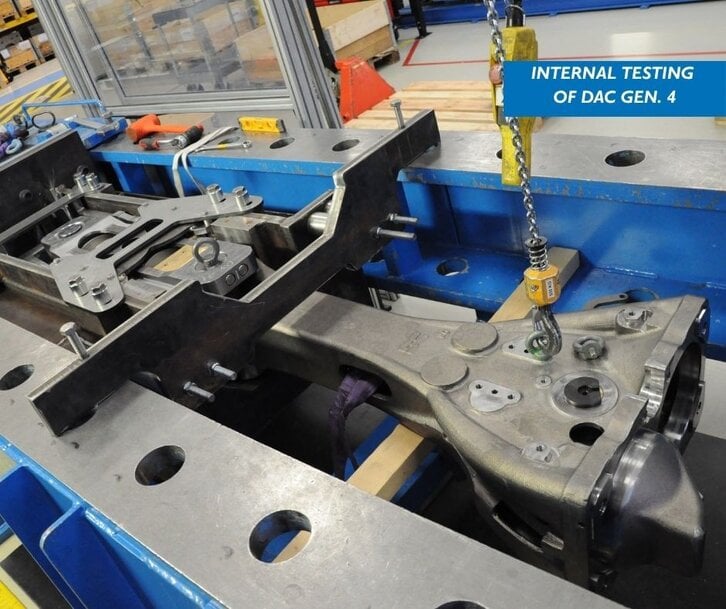

Upgraded mechanical design of Dellner DAC Gen. 4

To facilitate the deployment of couplers, Dellner has developed a new installation tool enabling quicker and easier DAC installation in wagons, reducing downtime and improving workshop efficiency.

1. Enhanced Draft Gear

A new pre-tensioned draft gear offering greater functionality and mechanical resilience in demanding conditions.

Optimised design for easier handling during installation.

2. Reinforced Mechanical Coupler

Built to last: a single-piece casted coupler head and shank dramatically increases structural strength and long-term durability.

Dellner’s next-generation Digital Automatic Coupler (DAC Generation 4) was lately undergoing extensive derailment testing at the TÜV Süd facility in Görlitz, Germany – marking a major milestone in the journey toward safer, smarter freight rail. Link to article here.

This rigorous test campaign was designed to validate a key safety scenario: ensuring wagons equipped with DACs remain securely on track, even when pushed into braked wagons on curves. As the first derailment test series for the upgraded Dellner DAC, it sets a new benchmark in operational safety for automated freight systems.

Running over four weeks, the FP5-DACtiVate, Flagship Area 5 program results will provide crucial insights into DAC’s performance under real-world stress.

With every advancement, Dellner reaffirms its commitment to driving a fully digital, safer and more sustainable future for the global freight rail industry

With Dellner, the future of freight is not just coming – it’s already here.

Dellner’s next-generation Digital Automatic Coupler (DAC Generation 4) was lately undergoing extensive derailment testing at the TÜV Süd facility in Görlitz, Germany – marking a major milestone in the journey toward safer, smarter freight rail. Link to article here.

This rigorous test campaign was designed to validate a key safety scenario: ensuring wagons equipped with DACs remain securely on track, even when pushed into braked wagons on curves. As the first derailment test series for the upgraded Dellner DAC, it sets a new benchmark in operational safety for automated freight systems.

Running over four weeks, the FP5-DACtiVate, Flagship Area 5 program results will provide crucial insights into DAC’s performance under real-world stress.

With every advancement, Dellner reaffirms its commitment to driving a fully digital, safer and more sustainable future for the global freight rail industry

www.dellner.com