The Importance of Brazing in the Manufacturing and Assembly of Railway Products

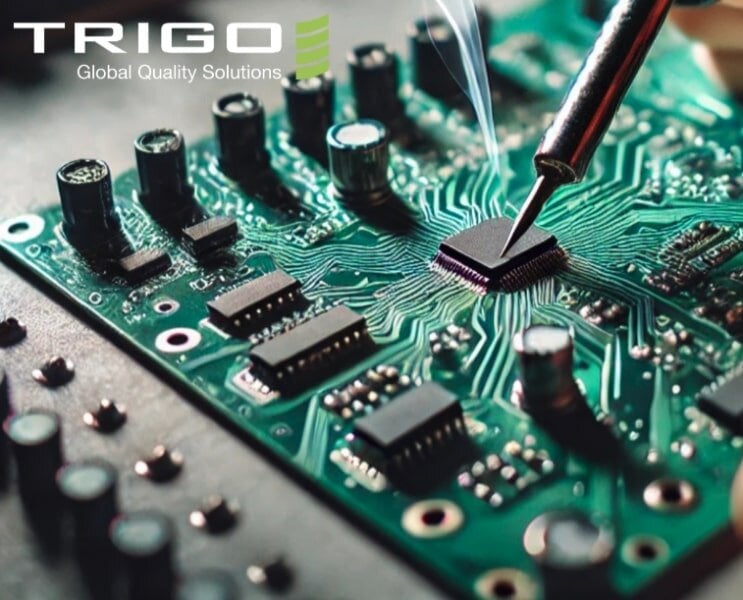

Brazing is widely used in the railway industry to assemble components that require strong and reliable joints with good thermal and electrical conductivity.

It is particularly useful for joining different metals, complex geometries, and thin-walled structures. However, the challenges of controlling and improving brazed assemblies in railway products are also significant.

How Does TRIGO Aerospace, Defense & Rail Address this Issue?

TRIGO Aerospace, Defense & Rail, a global leader in quality control and engineering services, plays a crucial role in the control and optimization of brazing processes for railway products:

1. Quality Control of Brazed Joints TRIGO Aerospace, Defense & Rail, with its mastery of international and manufacturer standards for this special process, offers effective quality control services to verify the integrity of brazed joints. This includes visual inspections, dye penetrant tests, and non-destructive ultrasonic testing to ensure that finished products (HVAC, busbars, energy storage systems, braking systems, bogies, reflectors, etc.) meet safety and performance standards.

2.Training and Certification TRIGO Aerospace, Defense & Rail offers training programs for brazing inspection technicians, ensuring they master best practices in the railway environment.

3.Customized Engineering Solutions TRIGO Aerospace, Defense & Rail collaborates with manufacturers and their suppliers to develop customized engineering solutions, combining:

- Production monitoring including brazing operations

- Continuous improvement of this special process through training and production organization consulting

- Workplace audits

This is done in more than 30 countries worldwide.

www.trigo-group.com