railway-international.com

21

'24

Written on Modified on

Schaeffler Improved rail vehicle availability with technology- and platform-agnostic condition monitoring

Onboard condition monitoring system that can process data both locally and via the cloud. Proof-of-concept presentation at InnoTrans 2024. Track-based condition monitoring system with acoustic cameras now in use.

www.schaeffler.com

At InnoTrans 2024, Schaeffler is presenting a broad array of new condition monitoring solutions. These include its own self-developed monitoring systems – both vehicle-based and track-based – and condition monitoring as a purely software solution in the context of collaborations. Following is a brief overview of the company’s current range.

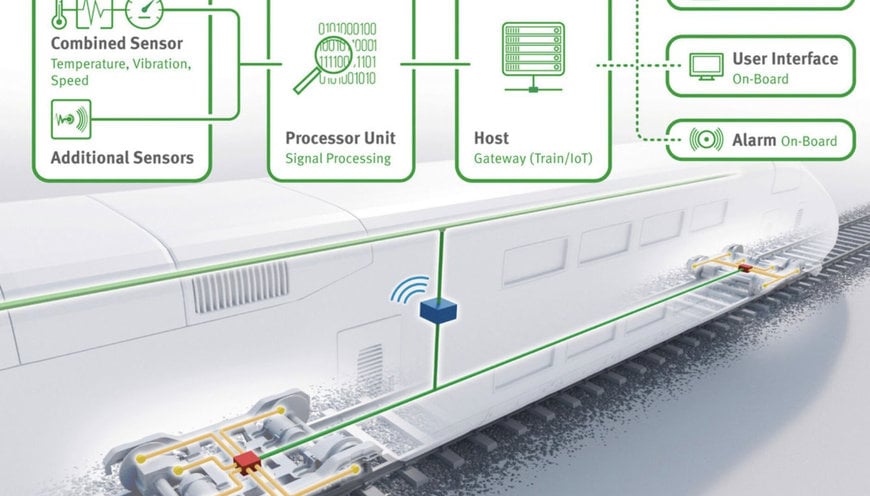

Wired onboard condition monitoring

Schaeffler has further developed its wired onboard condition monitoring system (CMS) for the monitoring of complete motor and trailer bogies in passenger trains and locomotives. Customers can now either use the CMS with cloud data integration or have the condition data analyzed locally on board the vehicle. If they opt for the latter, the data is stored on an onboard server and is analyzed and processed onboard using process modules. A central process module functions as the interface and protocol converter between the CMS and the higher-level train system. This new improved version of the CMS retains the tried and tested combination sensors for recording vibrations, temperatures and rotational speeds. These sensors reduce the amount of bogie cabling and installation work to a minimum.

Data matrix codes and track-based condition monitoring

Another development focus at Schaeffler is the use of data matrix codes (DMCs) for applications that go beyond digitalized maintenance of axlebox bearings. The idea here is that by digitally linking the axlebox bearings to the wheelset and bogie assemblies further up the hierarchy, it is possible to significantly extend the benefits of track-based condition monitoring systems. Specifically, this approach enables cost-effective stationary monitoring systems to identify individual vehicle components. Accordingly, at InnoTrans 2024, Schaeffler and project partners SBB, Stadler and Alstom are giving a proof-of-concept presentation of a system that digitally maps the hierarchy of the components in a train.

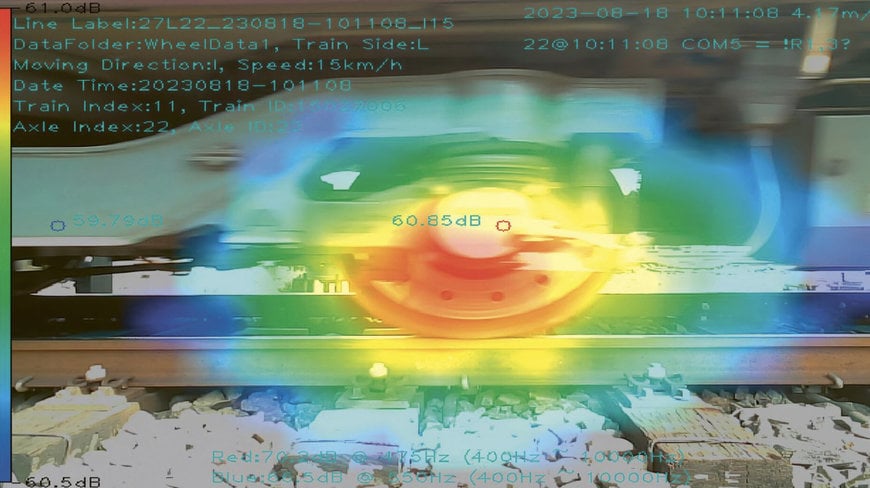

Track-based CMS with acoustic camera

Compared with conventional “hot box” detection systems, the Acoustic Thermal Management System (ATMS) developed by the joint venture between Schaeffler and CARS Railway Technology Co. Ltd. gives significantly longer warning times – in the vicinity of about a week. The stationary, track-based acoustic camera identifies the noises emitted by ailing bearings. With the aid of the cloud-based ATMS, the technology, working in real time, generates sound intensity maps – much like thermal images – digitally overlays them onto a photograph and uses this information for fault diagnosis and trend analysis. The ATMS system is already being used successfully in the Beijing Subway. The aim is to raise the profile of this technology in Europe and realize the first projects there.

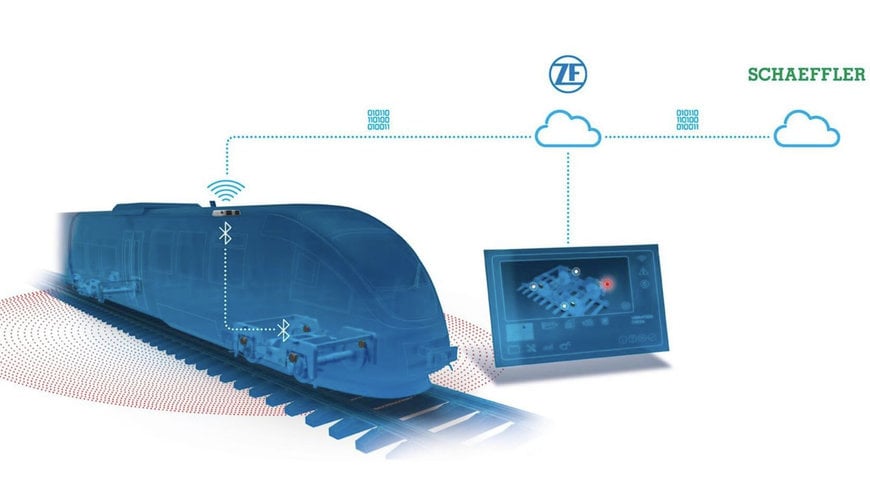

Wireless monitoring system as part of a cooperative project

As well as its wired condition monitoring system, Schaeffler offers a wireless axlebox-bearing condition monitoring solution that does not include any Schaeffler hardware. This is made possible by a cooperative project with automotive supplier and gearbox manufacturer ZF based on the latter’s connect@rail platform. The ZF contribution to the project is a battery-powered vibration and temperature sensor that is attached to the axlebox bearing housing. ZF’s wireless Heavy Duty TAG sensor transmits vibration and temperature data via radio/Bluetooth to the VCU Pro Onboard Unit gateway and from there to a ZF cloud. ZF then uses the data to analyze the condition of gearboxes and wheel tires (wheel tire wear). For its part, Schaeffler provides a software module that builds on this ZF solution to enable analysis of axlebox bearing condition.

Outlook and strategy

Schaeffler and numerous OEMS are leveraging their domain knowledge and unique perspectives to offer specialized solutions for monitoring the condition of traction motors, gearboxes, bogies, rolling bearings and tracks, etc., in the rail industry. Doing this by using open platforms and joint ventures will help to reduce the number of siloed solutions on the market and ensure greater acceptance among rail operators. The benefits of this will flow to the entire industry.

www.schaeffler.com