railway-international.com

06

'23

Written on Modified on

MICRO EPSILON PERFORMS TEMPERATURE MONITORING OF DRIVE BATTERIES DURING HANDLING AND TRANSPORT

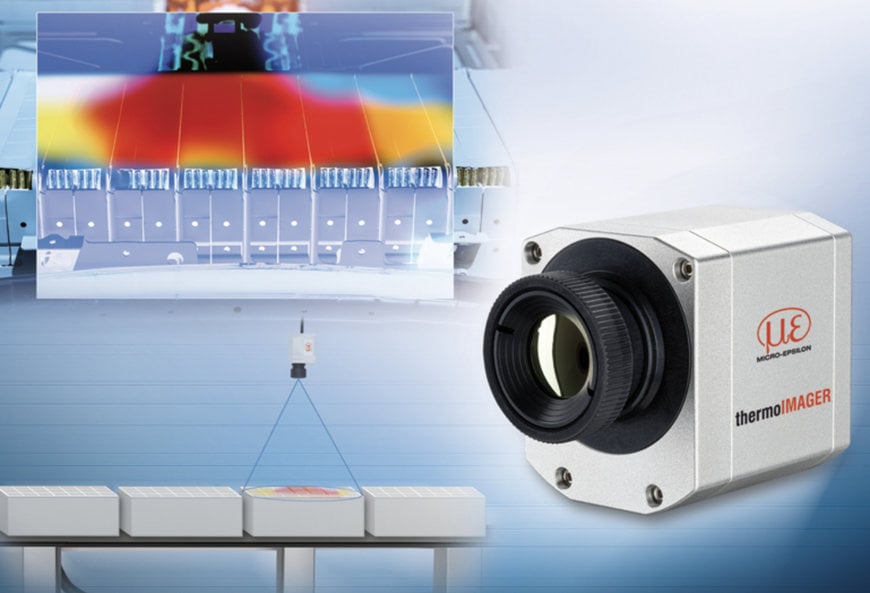

To minimize the risk of fire during battery assembly, drive batteries are already checked for thermal anomalies during incoming goods inspection. The high-resolution thermal imaging camera thermoIMAGER TIM QVGA is used for this purpose.

An alarm is triggered when the temperature is exceeded. This allows defective battery packs to be sorted out at an early stage.

To minimize the risk of fire in production plants for drive batteries, the batteries are inspected for thermal anomalies as soon as they are delivered. A high-resolution thermal imaging camera, thermoIMAGER TIM QVGA from Micro-Epsilon, monitors the thermal properties of the drive batteries either during unstacking or on a conveyor belt. For this measurement task, the camera is mounted stationary or guided to the measuring point by a robot arm. With a single, non-contact measurement, it detects the temperature profile of the entire battery surface. The individual measurement is sufficient to reliably identify possible hot spots and defects on the battery. Thanks to a frame rate of 80 Hz, short cycle times and high throughput can be achieved.

The TIMConnect software included in the scope of delivery triggers an alarm when the measured temperature exceeds the defined maximum value. Defective battery packs can be sorted out at an early stage via the alarm and snapshots can be taken at the same time. Snapshots can also be taken at regular intervals for process documentation.

Thanks to this complete system, the entire inspection, selection and documentation process for both the handling and transportation of drive batteries can be automatically and reliably executed. This increases operational safety and helps to detect fire hazards at an early stage.

Characteristics

- Temperature range from -20 °C to 1900 °C

- Long-life operation due to non-contact and wear-free measurement

- Ideal for OEM applications

- Real-time thermography with license-free software

- Compact design including USB port / optional Gigabit Ethernet

Easy process integration

Advanced interface concepts enable the integration of the infrared cameras into networks and automated systems:

Advanced interface concepts enable the integration of the infrared cameras into networks and automated systems:

- USB cable extension up to 100 m via Ethernet or up to 10 km via glass fiber

- Process interface (PIF) as analog input/output (0/4-20 mA) and digital output (potential-free relay output)

- Software interface via Dynamic-Link-Library (SDK) and COM port