railway-international.com

24

'23

Written on Modified on

Westermo technology used to operate world’s steepest cogwheel railway

The Pilatus-Bahnen railway was built over 130 years ago and is still the world’s steepest cogwheel railway. The train climbs the path from Alpnachstad to Pilatus Kulm, with passengers able to view flowering alpine meadows, striking rock formations and snowfields.

The railway has become one of Switzerland's most successful tourist attractions. Because of its popularity and large number of passengers, the railway needed larger and faster rail vehicles equipped with modern technology. Reliable and robust data network technology from Westermo was chosen to support the operation of these new trains.

Reliable data communication

The train control system used in the original trains was based on mechanical and electromechanical control elements. For the new larger and faster trains, a modern, electronic train control system from Actemium Schweiz AG LeitTec (Actemium) was installed. In order to establish a connection between trackside control units and moving trains, reliable wireless data communication was required.

A network that offers high levels of availability is essential for automatic train operation and communication-based train control systems, such as the PbS (position based signalling) developed by Actemium and used on Pilatus-Bahnen railway. With the exceptionally high reliability demands, a wireless network solution developed specifically for train-to-ground communication was required.

Westermo was chosen for the project by Pilatus and Actemium. Westermo's extensive experience in developing high-availability data networks for railway systems and its broad range of robust data communication products that meet the reliability and availability requirements were critical factors in this decision.

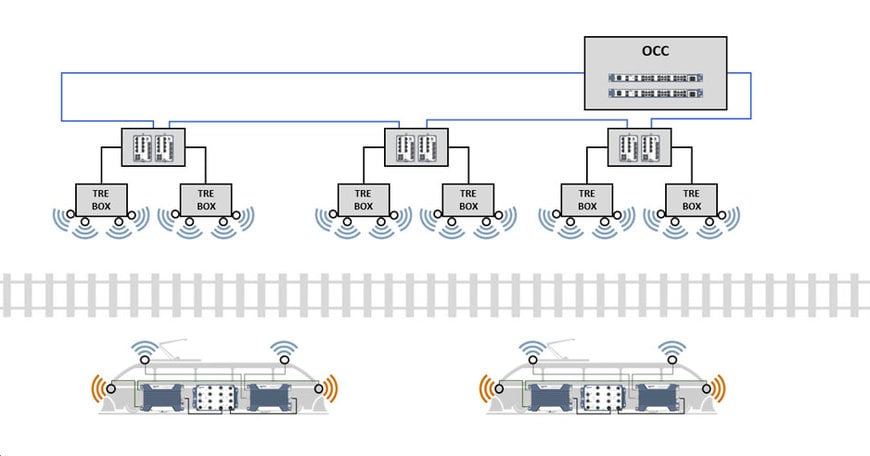

Train-to-ground’ Ethernet architecture and rear-end detection of trains.

"We chose Westermo because the collaboration was constructive and very engaging right from the start of our discussions. A project like this one has never been built before and is essentially a prototype. To be able to accomplish this project, we needed partners like Westermo who actively contribute their know-how and support us with planning. Ongoing project changes were always supported and professionally implemented by Westermo. We could count on them at all times," said Patrick Blaser, Operations Manager and Member of the Executive Board at Pilatus.

Secure data network

Westermo engineers designed, delivered and installed the data network directly on the mountain in close collaboration with Actemium. Based on a redundant Ethernet ring architecture, the network consists of wireless and wired Westermo devices designed for maximum reliability.

The network had to balance two critical requirements. While high technical requirements had to be met, infrastructure costs had to be optimised to the greatest extent possible, at the same time. Network security also played a very significant role in the planning.

The ICT minimum standard, the Swiss government's cyber security recommendations for critical infrastructures, was also taken into account. It was important to include network security in the planning process from the beginning and to implement it gradually. Through meticulous planning, an encrypted data network with several security zones, monitoring and surveillance systems was created.

Redundant Ethernet architecture FRNT (fast recovery network topology), Westermo's own ring protocol for high-availability Ethernet networks provided the network redundancy. The ring architecture ensures data transfer via other paths in the unlikely event of a device or network link failure. Furthermore, to ensure that the network can be operated securely and is protected from the outside, a number of security functions, such as data encryption, port security, active firewalls and other mechanisms for a secure data network, were already taken into account in the concept and later implemented.

The Trackside Radio Equipment Box (TRE Box) being installed on Mount Pilatus. The commissioning of the trackside and onboard data networks began in June 2022.

Westermo Ibex-RT-370 infrastructure access points were installed trackside to provide WLAN connection to the vehicles, along with redundant routing switches with firewall functionality in the stations. The network onboard the trains is based on Westermo Viper-212A managed routing switches and Ibex-RT-320 wireless clients that communicate over Wi-Fi with the trackside access points. This train-to-ground communication network setup ensures reliable communication between the trains and the control system.

In addition, a collision warning system between the trains was implemented using Westermo wireless technology. A WLAN connection is automatically established between two vehicles when they approach each other. This connection allows the steering systems to exchange data, enabling them to travel virtually in tandem and avoid collisions.

There is often over 10 metres of snow on the Pilatus summit in winter. In order to protect the infrastructure from these masses of snow and water, it is partially dismantled in autumn and reassembled in spring. In order to simplify and streamline this process, a special `trackside radio equipment (TRE) box was developed and implemented by Westermo, containing WLAN access points, antennas and power splitters.

These TRE boxes were delivered to Pilatus Bahnen fully wired, tested and configured, allowing for cost and time savings during the installation and commissioning. Thanks to a sophisticated assembly and disassembly system, the boxes can be easily dismantled in the autumn and reassembled in the spring. This also ensures that the antennas mounted on the TRE box are correctly aligned again after reassembly.

View from inside a train as it is heading to the top of Mount Pilatus.

Mount Pilatus is an extremely unique place, with its highest point over 2000 metres above sea level and exposed to extreme geological weather conditions. To ensure the installation was successful, all companies involved had to work closely together. Occasionally, work could not be carried out as planned due to geological or weather conditions, requiring a high degree of collaboration and flexibility.

"Throughout the project process, we were able to rely on Westermo and benefit from their expertise in secure, industrial networks and WLAN systems. Together, we developed network concepts with integrated cyber-security. Additionally, Westermo was on-site during commissioning to support us. This saved us a lot of time and money. We will also rely on Westermo for future projects since reliable data networks are the foundation of our success," Peter Tschan, Project Manager at Actemium, a key participant in the project, states.

www.westermo.com