railway-international.com

22

'22

Written on Modified on

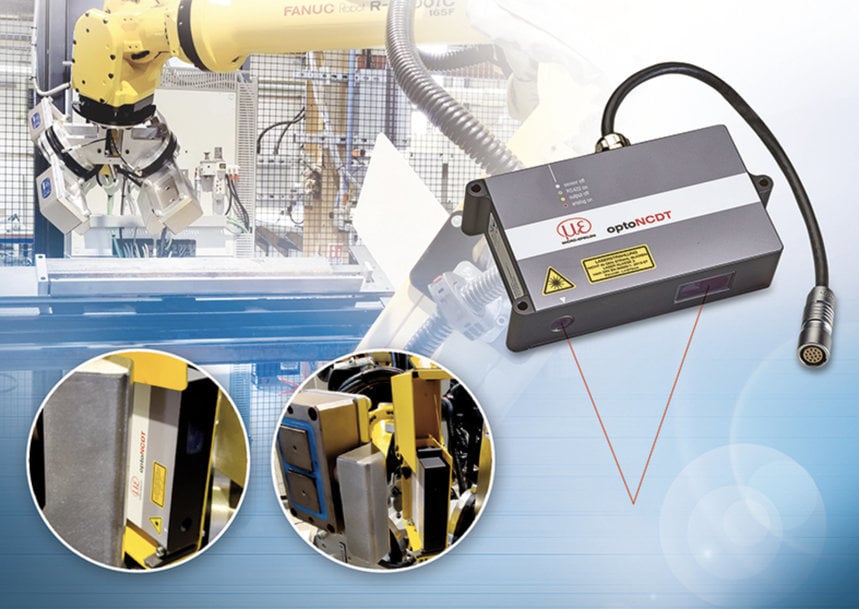

MICRO-EPSILON: MEASURE RAILWAY FISHPLATES AUTOMATICALLY

Mills CNC uses Micro-Epsilon laser sensors for the automatic inspection of large, hot-rolled railway fishplates made of steel. These fishplates join two rails together and must be as straight and flat as possible.

In a machine tool automation cell specially developed by Mills CNC for this task, both the bend and a twist of the fishplates are determined. For this measurement task, an optoNCDT 1750 Micro-Epsilon laser sensor is mounted on a robot. The sensor offers a large measuring range of 750 mm. Its compact sensor design and direct data output without external controllers enable easy integration.

First, two magnetic grippers position the measuring object. A robot then guides the laser sensor along the fishplate edges. The optoNCDT 1750 measures the fishplate in eight different positions. At each position, the sensor is moved a short distance and generates an averaged value, which is transmitted from the sensor via the interface module IF2030/ENETIP (EtherNet/IP) to a computer. The optoNCDT 1750 laser sensor combines a large measuring range with high measurement accuracy. This is why the sensors is specially suitable for measurement tasks on the robot.

The evaluation unit developed by the customer computes and monitors whether the component is within the manufacturing tolerances. The bend must not exceed a height difference of 2 mm over a length of 1 m. If it does, the component can be sorted out and reworked before the next machining step, which saves machining time.

www.micro-epsilon.com