Smart HPT

A Brilliant Way to Save Fuel and Reduce Emissions.

Introduction

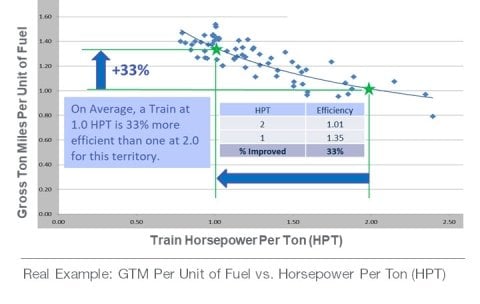

In the journey to higher levels of fuel efficiency and lower greenhouse gas emissions, control of horsepower per ton (HPT) is essential

Here’s why: Horsepower demands vary based on train make-up, terrain, and other operating conditions. When railroads build trains, they need to make sure that they have enough locomotive power to get over the steepest grade (ruling grade) on the route. What typically happens, however, is that the ruling grade is just one small segment of an entire trip. So, in an effort to meet the needs of the most critical condition, there is excess horsepower expended during the balance of the trip. And that excess horsepower results in higher fuel consumption and associated emissions.

The key to solving this is optimizing horsepower per ton.

Horsepower Per Ton: A Primer

The ratio of locomotive power to the weight of the train is horsepower per ton. Specifically, it is calculated by summing the horsepower of all locomotives in the train and dividing by the weight (in tons) of the train.

The resulting HPT ratio is important because it is a metric that is used to inform how much power is needed for a given train. Depending on how much cargo it carries, for example, one train may have 75 cars and another train may have 100 cars. So, using HPT, or horsepower per ton, as a metric helps to normalize the power utilized for all trains on that route. In doing so, it reduces the number of locomotives used during any segment of the trip.

So, how do railroads manage to a specific HPT?

Challenges

Managing horsepower per ton is challenging.Here's an illustration:

- Let’s say we have the perfect train: two locomotives with 4,000 HP each and 8,000 trailing tons. For this example, my railroad rule is to run at 0.5 HPT. So, that would mean manually isolating one locomotive. Now, let’s make this more like the real world: one more car shows up. So now my train is 8,100 tons. Since the operating rule is 0.5 HPT, and the only switch you have is to either turn on or off a locomotive, that train goes from 0.49 HPT to 1.0 HPT. So, you end up having to operate two locomotives for the entire trip.

Compounding this is the difficult task of manually controlling HPT. It is hard for humans to figure out how much power they need versus how much they don’t need at each segment of the trip. From considering train length, speed restrictions, terrain, and weather conditions, the process requires a lot of manual and mental efforts. In addition, tactics like limiting the notch or shutting off certain locomotives, require crew compliance and for the crew to remember to do it. And all of this is against the backdrop of a constantly changing environment. The result: overpowered trains and inefficiency.

So, how do railroads solve these challenges and reap the benefits of optimized horsepower per ton? The answer is automation through Smart HPT.

Smart HPT

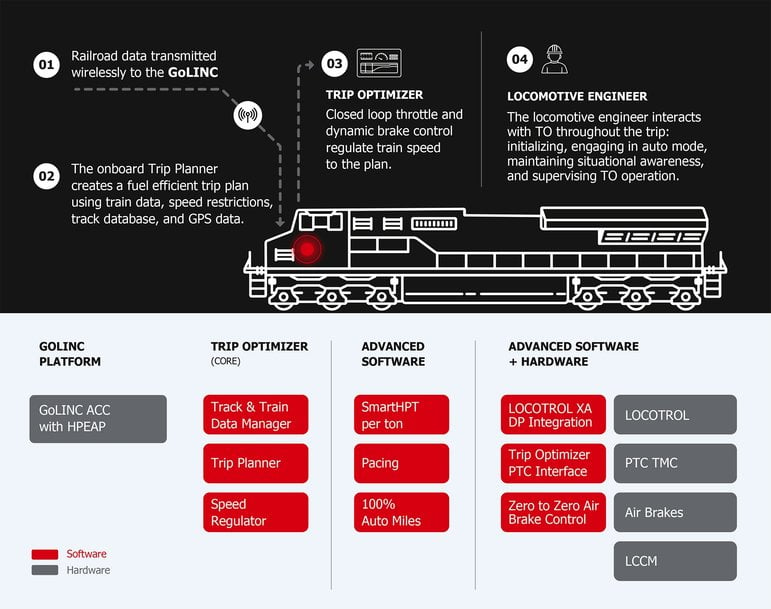

Smart HPT optimizes train performance for a given horsepower per ton target.

The foundation of Smart HPT is built on Trip Optimizer cruise control. Because Trip Optimizer has data on the train make-up and weights and understands the terrain and topology of the track, Smart HPT can determine exactly what horsepower is needed at every point along the route. The result: railroads save fuel and reduce emissions without impacting velocity – automatically.

Smart HPT is comprised of three features:

- Smart Planner: Avoids excessive horsepower by limiting train HPT through modification of the Trip Optimizer plan to match the railroad’s requested HPT limit for the train and the route. This powerful capability automates limiting the HPT based on the location of the train. It prevents an overpowered train.

- Auto Idle: Identifies excessive horsepower and automatically idles trailing units without adjusting train speed. This feature recognizes that locomotive engines are more efficient when run at higher RPMs, so it is better to have one locomotive in, say notch 5, than to have three locomotives in notch 2. Any time that auto idle sees that the Trip Optimizer plan speed can be maintained with just one locomotive’s power, it then idles down the trailing units and runs with just the lead unit online.

- Network Control: Automatically isolates locomotives in the lead consist using intra-consist control. Isolated units will then follow their railroad-specific rules for shutting down. This feature lets the lead unit command the trailing unit to isolate, without someone going back and physically flipping switches. That is a further savings of fuel because then the locomotive that is isolated is managed by Auto Engine Start Stop (AESS). So, it can shut down completely and saves fuel by not running at all.

In addition, Smart HPT can determine if a locomotive is not operating to the plan speeds and self-adjusts accordingly, bringing power back on to avoid stalls and maintain the schedule.

Conclusion

Smart HPT takes the guesswork and mental planning out of controlling horsepower per ton – without slowing the train down. The result:

- Fuel savings and emissions reduction: 5-10% (5% EPA certified)

- Improved train handling