railway-international.com

06

'22

Written on Modified on

PANDROL LAUNCHES NEW PLA EVO ALUMINOTHERMIC WELDING PROCESS

Global rail infrastructure specialist Pandrol, have announced the exciting launch of their PLA Evo welding process, an evolution in bonding for aluminothermic conditions.

What is the PLA Evo process?

The PLA Evo is the latest optimised welding process, designed to be easy to use, improve performance and be fully compatible with the Pandrol aluminothermic welding product range.

PLA Evo is suitable for use on a 25mm welding gap (25 +/-2 mm) and is tested and approved against the EN 14730-1 European Standard which defines the laboratory tests and requirements for approval of an aluminothermic welding process.

How does the PLA Evo work?

Optimised thermal conditions are created by balancing the pre-heating, the redox reaction, and the solidification. When used with the high flow preheater, secure and safe welding is guaranteed.

What are the benefits of PLA Evo?

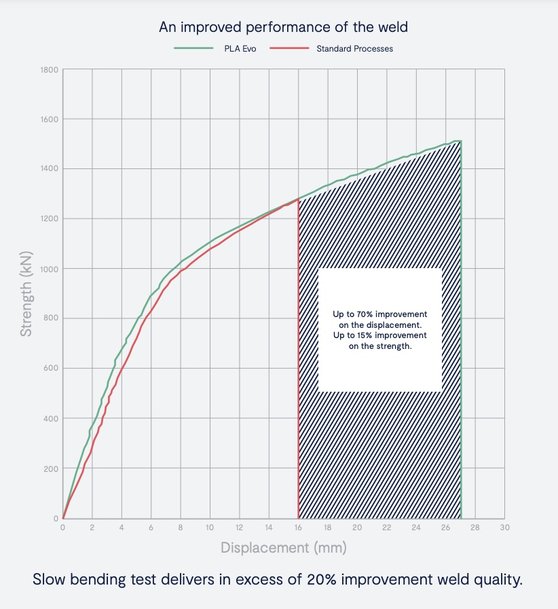

The PLA Evo process creates an improved metallurgical quality maximising the life of the weld and reducing maintenance costs. Designed for compatibility with Pandrol's High Flow Preheater, it provides ergonomic improvements for the welder and saves time.

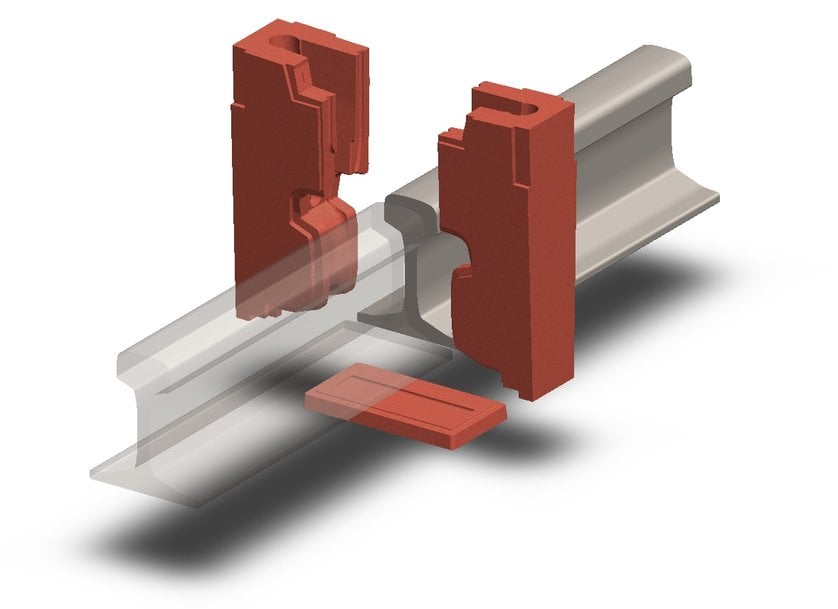

PLA Evo delivers improved performance with its innovative 3-piece mould design. The continuous geometry eliminates discontinuity under rail foot and the new optimised internal hydraulic geometry improves flow.

How can I start using PLA Evo?

PLA Evo is a fully supported process, and full training can be provided locally by Pandrol welding experts or directly at the Pandrol Training Academy. The PLA Evo process is fully compatible with Pandrol Connect: Pandrol's smart welding traceability app designed to support aluminothermic welders.

Frédéric Delcroix, Technical Director of Welding at Pandrol, comments: "The PLA Evo welding process is a fantastic innovation and improvement to efficiency in aluminothermic engineering. We are pleased to now roll out this process across our delivery teams and see the great impact and quality production we know this technology will provide."

www.pandrol.com