railway-international.com

27

'21

Written on Modified on

Tsubaki eases machine design with heavy duty, versatile Pin Gear Drives

Providing superior tangential force compared to large gears, Tsubaki Pin Gear Drives are a cost-effective and versatile solution for builders of heavy-duty automatic machinery.

Designed to expand possible configurations of linear or rotary drive units, Tsubaki Pin Gear Drives are an ideal selection for applications in the metal, industrial, robot, machine tool, infrastructure and rail sectors.

Tsubaki Pin Gear Drives feature either a wheel or rack of pin structures combined with a gear. The gear itself is designed with a specialist tooth pattern that engages continually with the wheel or rack to provide smooth motion. This is thanks to an approximate involute tooth profile which ensures the gear can move across the pins without slip. Each gear has hardened teeth, enhancing durability in operation. These inherent features provide an exceptional load capacity and large transmission torque, ideal for the needs of heavy machinery.

However, this capability doesn’t translate to greatly increased cost, as Pin Gear Drives, especially in larger sizes, provide similar performance to gear sets at a more competitive cost point. The speed ratio can also be increased for a lower cost compared to sprocket and roller chain drives, both of which do not provide such impressive load or torque capacity. Unlike roller chains, Pin Gear Drives do not require tension adjustment, improving uptime and cost-effectiveness.

Another area where Tsubaki Pin Gear Drives excel is the increased design versatility they can provide to machine builders. The optimised engagement of pin and gear means that wheel diameter or rack length can be specified with complete freedom. A segmented, modular design allows for designers to increase the size or complexity of Pin Gear Drives seamlessly. Furthermore, this ensures increased ease of installation, as segments can be fitted with minimal fuss, even for large, complex systems. The same is true of disassembly, which consequently streamlines any maintenance work. By fitting the gear within a wheel or rack, machine builders can also achieve a more compact design. Units are available in steel, stainless steel and surface coated variants, further enhancing versatility.

Tsubaki Pin Gear Drives are an ideal selection for applications in the metal, industrial, robot, machine tool, infrastructure and rail sectors.

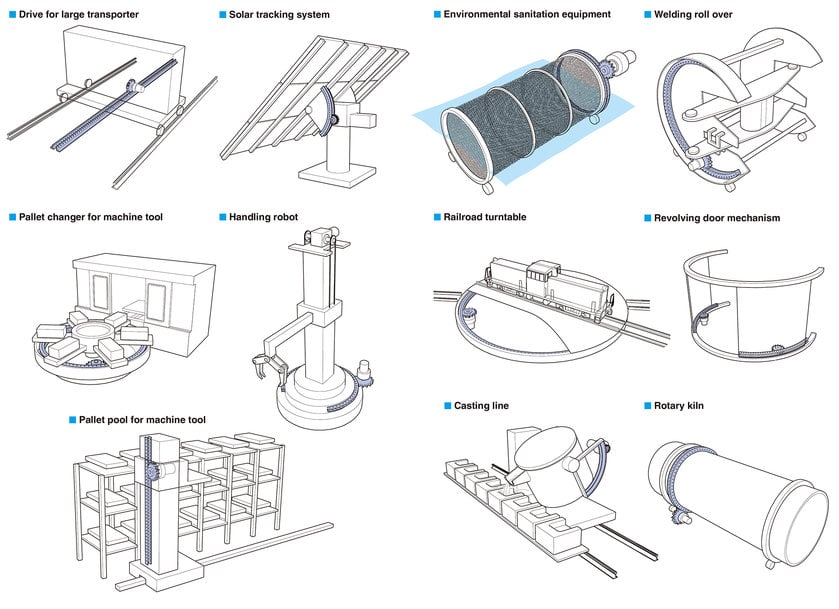

Versatility of specification ensures suitable applications across multiple sectors. Usage in heavy load transfer carriages, industrial furnaces, environmental sanitation equipment, welding roll overs, railway turntables, revolving door mechanisms, casting lines, rotary kilns, large transporters, solar panel tracking systems, handling robots, pallet changers and pallet pools for machine tools is common. Tsubaki can work directly with an end user or machine builder to provide custom solutions to exactly fit an application.

To provide ease of specification and enhance system reliability, Tsubaki offers a wide range of compatible options. Machine builders can select gear motors, gearboxes, drive chains, sprockets, servo motor reducers, locking devices as well as hose and cable carrier systems.

With a global capability, Tsubaki can dispatch expert engineers to customer facilities to assess equipment and select an optimal Pin Gear Drive solution. On-site support is also available post purchase, providing additional assurance to machine builders and operators. By selecting Tsubaki Pin Gear Drives, end users and machine builders not only gain access to a heavy duty, versatile and cost-effective solution – but also all the support required to ensure continued uptime post installation.

www.tsubaki.eu