railway-international.com

14

'21

Written on Modified on

Basaltex, Rail Industry pioneer, reaches new milestones with Econcore

Testing and development achieve rigidity and safety milestone fornew composite of basalt fibres forrail carriage interiors

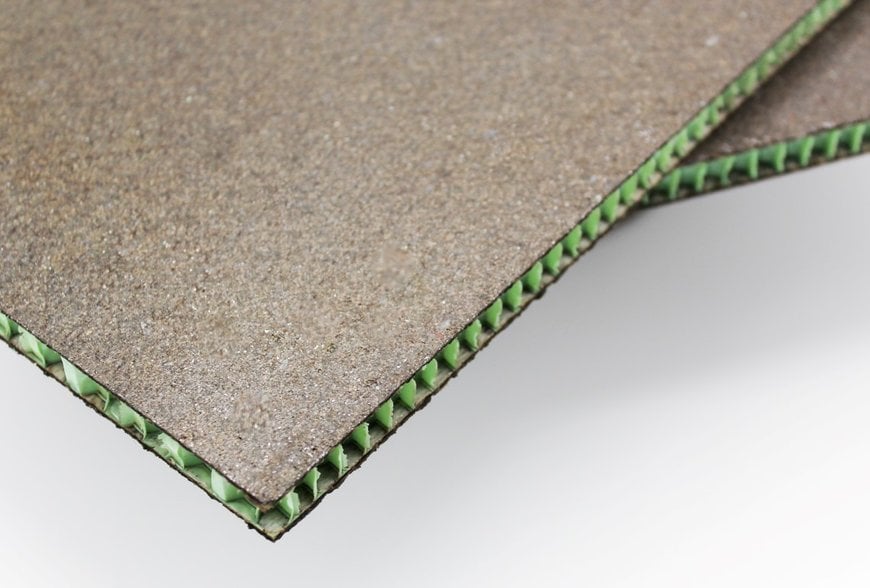

Basaltex, pioneers in innovative uses of basalt fibres, has achieved a significant milestone in developing and testing a new composite material solution comprising fibers of basalt combined with Econ Core’s patented honeycomb technology.

This new material development has greatly improved fire resistance and is highly rigid , as well as the usual honeycomb properties of light-weighting.

The company has tested the composite of basalt fibres, a bio resin and rPET honeycomb.

Filaments of only stone fibres are extruded at a temperature of 14500C, similar to glass but with a number of advantages, not least the absence of boric acid in the process.

Combining this ecological fibre with EconCore’s sustainable technology using rPET, and the bioresin polyfurfuryl alcohol -100% derived from a waste stream of sugar cane-make this a very sustainable and environmentally friendly product, unlike the majority of thermoset solutions in this type of application.

Railway applications require materials with enhanced fire resistance and the testing has shown that the Econ Core-Basaltex solution fits these needs well, at the same time offering the perspective of drastic weight reduction against traditional monolithic GRPs used rather widely in train interiors.

Such sandwich panel could be deployed in applications such as cladding panels, partitions, tables and flooring. The thermoset skin layers give a fast cure at elevated temperature, meaning short cycle time and enabling automated production’.

As well as the railway interior application, this new material combination could be used in any application that requires fire performance combined with alow weight.

Wouter Verbouwe, Basaltex’s R&D manager,commented: “To have completed the testing of this new composite of basalt fibre is a major milestone. We have designed it specifically for rail carriages and are now introducing it to the industry.”

Jef Delbroek, Project Engineer at EconCore added: “Honeycomb and stone? Some combinations don’t automatically come to mind,but this material solution could enable converters to combine fire safety, light-weighting and sustainability in an elegant way. We look forward to seeing how the railway industry will respond to this novel material combination and hope to arouse interest of other industries as well.”

www.jeccomposites.com