Siemens Mobility to upgrade and modernize 450 km of the Taiwan rail network

Siemens Mobility is pleased to announce that it has signed a €231 million contract with the Taiwan Railways Administration (TRA) for the implementation of the “Taiwan Railway Smart Electrical Systems Upgrade and Signalling Interlocking System Update Project.”

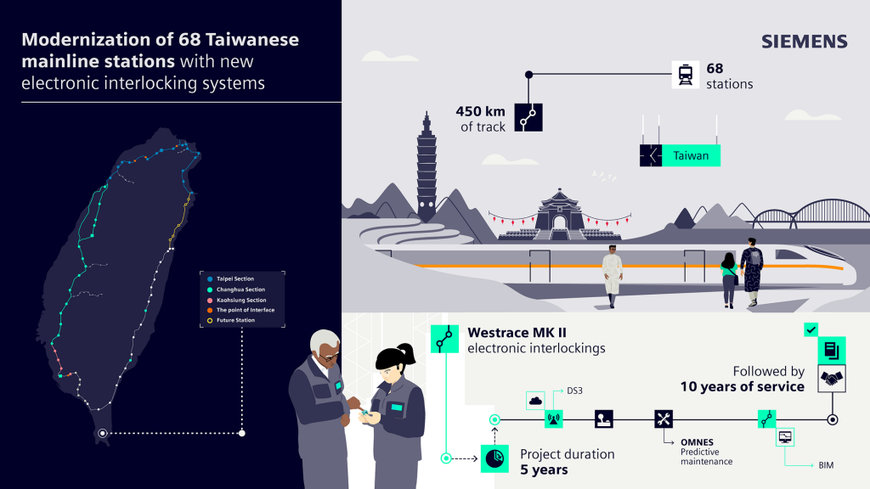

- €231 million contract to install an electronic interlocking signaling system at 68 stations and cover 450 km of Taiwan Railway

- Upgrades will improve the rail capacity, safety, efficiency and enhance passenger experience

The project primarily consists of replacing existing Relay Interlockings with new Electronic Interlocking (or EI) Systems at 68 stations that will cover 450 km of the island’s approximately 1110 km total railway network. As part of this contract, Siemens Mobility will provide 10 years of maintenance and the customer also reserves the right to procure EI systems for 10-additional stations. The modernization of the signaling system will allow the TRA to better optimize the operation and maintenance of the rail network.

“Siemens Mobility is delighted to have been selected to upgrade a significant portion of the rail network in Taiwan. Our state-of-the-art signaling and interlocking technology will augment operations throughout the network by increasing service reliability and availability, which will enhance the passenger experience,” said Andre Rodenbeck, CEO of Rail Infrastructure at Siemens Mobility. “This important project further underscores our leading position in the field for delivering automated and digital signaling systems that increases the safety and capacity of rail travel.”

Siemens Mobility will provide its EI system Trackguard Westrace Mk II, a highly flexible, microprocessor-based interlocking system suitable for both urban and mainline rail, which has been proven in over 1,200 applications worldwide. With versatility in configuration, flexible architecture, enhanced processing power, and multitude of connectivity possibilities, Trackguard Westrace Mk II offers railway operators real benefits in terms of total cost of ownership, improved punctuality, and greater capacity.

For maintenance, Siemens Mobility will utilize the OMNES predictive maintenance solution, an innovative digital services platform for railway signaling. OMNES unifies all maintenance tools on a single platform in a secure and customizable way by using the most advanced methods of digitalization. By minimizing and anticipating the impact of incidents, OMNES improves the overall efficiency of operations, with the aim of ensuring 100% service availability.

Siemens Mobility will also bring added value to this project through the usage of Building Information Modeling (BIM) methodology. BIM technology enhances the design process by enabling the digital recording of an entire rail network and uses digital models of a setting to record and manage relevant information and data. In addition, Siemens Mobility will install a prototype station with an interlocking based on the Distributed Smart Safe System (DS3), an innovative and digitalized safety platform, which enables the usage of commercial-off-the-shelf (COTS) server hardware and offers advantages like a geographical redundancy and limitless scalability.

The rail network managed by the TRA spans approximately 1,110 km and carries over 232 million passengers and 7.7 million metric tons of freight each year, linking the cities to the countryside. This is in addition to the separately managed high-speed rail that covers 350 km along the west coast, linking the capital Taipei to the southern city of Kaohsiung, and 131 km of mass transit in Taipei. The combination of metropolitan mass rapid transit systems with mainline rail forms a highly efficient rail-based transportation network.

www.siemens.com