OPTIMA XL

The optimal technology for catenary maintenance.

Received and used every night by Eiffage Rail, the OPTIMA XL is the latest generation of GEISMAR self-propelled road-rail vehicles, covering all catenary maintenance needs. Easily transportable by truck and quick to put on track, its elevators are high-performance for effortless and safe access as close as possible to the catenary component to be replaced. Versatile, it also allows working at height off the track with rich ergonomic features. Numerous players in the railway construction industry have shown interest in completing their equipment fleet and improving the performance of their worksites.

The famous VCP now has a cousin to help it meet new catenary maintenance needs! Named OPTIMA XL, it allows you to go even higher and further while maintaining its flexibility in terms of transport, track setting and use.

The OPTIMA XL is one of the ranges of compact road-rail machines widely used in catenary maintenance methodologies in France, allowing to work efficiently in small teams, on short railway sections and in a relatively limited time.

Why was the OPTIMA XL designed?

The catenary works market requires several criteria that these vehicles must meet:

- To meet the latest legislation in catenary maintenance: to ensure the safety of the means and methods, to guarantee safe rail access, to provide a high quality site;

- Improve the efficiency of maintenance work: intervene quickly in narrow and limited time windows, ensure the productivity of operators, participate in better organizing the site, invest in multi-network equipment (railway, tramway, metro, …);

- To be more competitive to meet budgetary constraints: reduction of operating costs, return on investment, maintenance follow-up ;

- Improve ergonomics: greater operator comfort, simplification of tasks, ease of use.

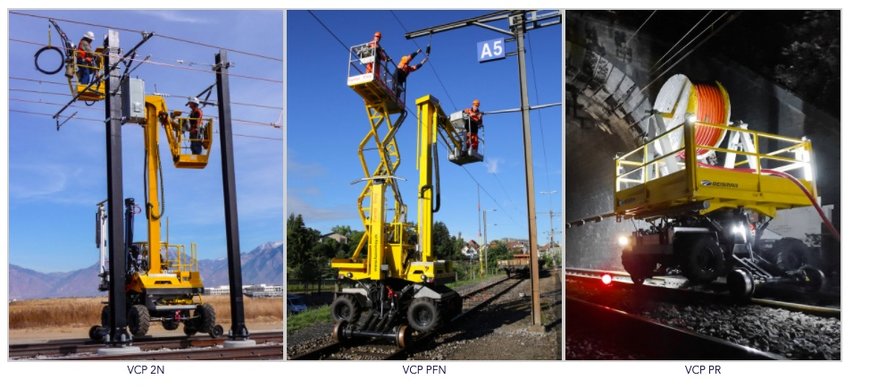

Since 2001, GEISMAR has been offering the VCP (worthy successor of the LAMA designed in 1995). It is a self-propelled and self-derailable vehicle of 5 tons that can be declined in several versions according to the work to be carried out (2N: 2 cradles, PF: platform, PFN/IPC: platform and cradle, PR: platform, PR-GR: platform-crane). Many units have been sold, particularly in France, and have aroused interest in China, the United States, Australia, Germany, Switzerland, Denmark, Morocco…in an increasingly competitive environment.

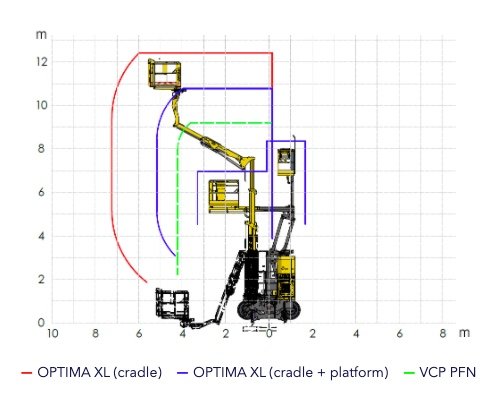

Covering 90% of the catenary maintenance needs for access to the supports (about 9 m high, 4 m offset), wires or droppers (about 7.7 m high), the VCP is nevertheless limited. Difficulties arise in accessing certain components such as the feeder or the tops of the poles, particularly on high-speed lines (25,000 VAC catenary). Indeed, to save time, it is sometimes necessary to reach a working height of more than 12 m and an offset of 6 m at the poles while accessing the catenary structures (bracket, cantilevers, …) and wires.

Meeting all catenary access needs on a compact 12 m² frame is therefore a great challenge for our GEISMAR Rhône engineers! The thermal engine, hydraulic transmission, aerial equipment (cradles, platform, pulling mast, etc.), driver’s cab and accessories must be placed in this small area. In addition, it is essential to guarantee the expected performance of the elevators (height, offset, on-board load) and the safety of the users with the constraints of the network (ramp, cant, traffic on the adjacent track, …).

What are the advantages of OPTIMA XL?

After more than a year of design, manufacturing and testing, the OPTIMA XL offers many advantages to meet the latest catenary maintenance needs.

Secure access to all catenary points

The OPTIMA XL is equipped with a telescopic elevator with a load capacity of 265 kg to access the tops and behind the poles (maximum working height: 12.6 m; maximum working offset: 7.2 m). In addition, a double cradle platform allows the operator to position himself at the level of the catenary structures for the replacement of the cantilevers and insulators as well as to check the wear of the contact wires or to carry out tilting operations. For this purpose, one platform with a load capacity of 300 kg is telescopic horizontally (maximum working offset of 3.3 m) and another platform with a load capacity of 120 kg is telescopic vertically (maximum working height of 8.3 m).

Fast and safe maintenance work

In order to operate on the French railway network, the OPTIMA XL complies with the most demanding standards such as SNCF NF58003. An anti-crossing system ensures that it does not enter the traffic gauge of the adjacent track. It is equipped with negative brakes and an oscillating axle that allows to circulate up to 20 kph on the tracks. The OPTIMA XL’s low-pressure tires allow off-roading up to 60% of the ramp without ploughing the ballast shoulders.

Reduction of time and costs by staying as close as possible to the construction site

Due to its compactness, the OPTIMA XL is a vehicle that can be easily stored along tracks so that it can be quickly returned to the construction site. It does not require a specific permit for its piloting and allows a quick return on investment. Its dimensions have been designed so that a tank trailer can carry two units and improve organization and logistics costs. Secure storage boxes help to store all the small daily equipment.

Easy to use, safe and ergonomic

The OPTIMA XL features a large, intuitive control screen, the telescopic elevator allows you to load material directly from the ground and many options and accessories have also been provided.

Hydraulic sockets can also be fitted to the elevators for crimping operations. A protective screen on the elevator basket prevents any contact with live parts of the adjacent track. A tilting mast is used to guide and support the wires. A removable lifting winch installed in the basket of the telescopic elevator helps to lift up to 150 kg of material. Retractable cantilever-holders are installed along the track side of the machine (for 4.5 m long cantilevers). A start & stop option stops the combustion engine and restarts it on request of a command. This brings additional savings in terms of fuel, noise and pollution reduction. Stabilizers ensure off-track work, on the track as well as on the road. In addition, it is possible to measure the height or catenary misalignment with the integrated pantograph and to be able to work in dry conditions with a protective cabin.

All these options are designed to further improve the OPTIMA XL’s response to catenary specific work environments and operator comfort. On request, non-thermal drives can be studied (electric, bimode thermal/electric) as well as remote maintenance and geolocation solutions.

Two OPTIMA XL are currently assisting Eiffage Rail teams in the maintenance of the catenary network in France. A third OPTIMA XL is already available for rental: don’t hesitate to try it out to improve your site methodologies!

www.geismar.com