railway-international.com

12

'25

Written on Modified on

The Effect of Temperature on Cork-Rubber Rail Pads Versus Rubber Pads on Railway Rolling Noise

Rail pads, the elastic elements placed between the rail and the sleeper, play a critical role in load transfer, vibration control and the long-term performance of railway infrastructure.

amorimcorksolutions.com

Rail pads, the elastic elements placed between the rail and the sleeper, play a critical role in load transfer, vibration control and the long-term performance of railway infrastructure.

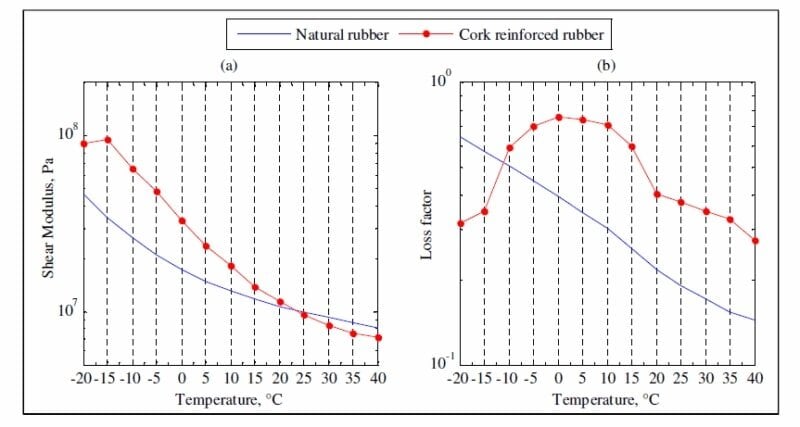

Their behavior depends mainly on two properties: stiffness, represented by the shear modulus, and damping capacity, expressed by the loss factor. Both are highly sensitive to temperature, which directly affects how vibrations propagate through the track and how much rolling noise is radiated. Previous research, particularly the work of Squicciarini et al. (2015), has shown that these effects are especially relevant when comparing conventional rubber pads with cork–rubber composites.

Figure 1. Shear modulus (a) and loss factor (b) measured at different temperatures. Results are obtained from 1 kHz frequency band. © Squicciarini et al., 2015

Temperature Sensitivity of Rail Pads

Rail pads must balance stiffness and damping, and for that purpose, two parameters are central, such as:

Shear Modulus: The shear modulus is a measure of a material’s rigidity against shear deformation. A higher shear modulus means that the rail pad is stiffer and deforms less under a given shear stress (load), while a lower shear modulus indicates that the material is softer and deforms more easily under the same stress/load.

Loss Factor: The loss factor is a measure of material damping, representing the ratio between the energy dissipated and the energy stored during cyclic deformation. Materials with a higher loss factor exhibit better damping behavior, as they dissipate more energy.

In this sense, temperature has a strong effect on both parameters. Tests carried out in a temperature-controlled chamber across the range of -20 °C to +40 °C revealed clear trends:

Rubber Pads: As the temperature increases, rubber pads soften. Their stiffness decreases and vibration isolation worsens, leading to higher rail vibrations and noise radiation. At around 40 °C, they are relatively soft and less effective. When cooled to –20 °C, their shear modulus increases by about six times, making them very rigid, but this mainly channels vibration into sleepers and ballast rather than reducing noise. Damping improves at low temperatures, although slightly.

Cork–Rubber Pads: Cork–rubber pads show an even stronger variation in stiffness with temperature, increasing their shear modulus by about ten to thirteen times between 40 °C and –20 °C. The advantage is that they remain stiffer than rubber at high temperatures, limiting the softening effect that amplifies noise. Around 0 °C they reach a peak in damping, with a loss factor up to 0.8, which significantly improves vibration suppression. This combination of higher damping in the transition region and greater stiffness at elevated temperatures ensures more stable performance across the full temperature span.

Implications for Rolling Noise

Rolling noise is one of the most significant sources of railway noise. It is generated when small irregularities on the surfaces of wheels and rails trigger vibrations that propagate through the track structure and radiate into the environment. Because rail pads regulate how these vibrations are transmitted, their response to temperature has a direct impact on noise levels.

Field measurements confirm this effect. Real train pass-bys have shown an increase of 3 to 4 dB(A) when ambient temperature rises from 0 °C to 35 °C.

Predictive models extend this finding, indicating that natural rubber pads may lead to noise variations of up to 6 dB(A) across the full –20 °C to 40 °C range. Cork–rubber pads, by contrast, show a smaller variation of about 4 dB(A). Although both materials are affected by temperature, cork–rubber offers greater stability and predictability.

The reason for this difference lies in the material composition. As rubber pads soften with heat, they lose the ability to control rail vibration. Cork–rubber pads, however, maintain higher stiffness and exploit their damping peak around 0 °C, which together limit noise increases at both high and transitional temperatures.

Cork–rubber pads offer a more consistent and reliable acoustic performance, less variation in passenger comfort, and lower maintenance needs since the track dynamics remain more stable throughout seasonal and daily thermal cycles.

Why Cork–Rubber Pads Offer a More Reliable Solution

Environmental temperature has a decisive impact on the mechanical and acoustic behavior of rail pads. Conventional rubber pads soften at high temperatures and stiffen excessively at low ones, leading to significant noise variations of up to 6 dB(A). Cork–rubber composites, on the other hand, combine the elasticity of rubber with the inherent stiffness and damping capacity of cork. This synergy ensures higher damping near transitional temperatures, greater stiffness at elevated ones, and overall reduced sensitivity to climate fluctuations.

By providing predictable stiffness and superior vibration attenuation across the full range of railway operating conditions, cork–rubber rail pads represent a resilient and effective solution for modern rail infrastructure. They improve noise control, enhance passenger comfort and reduce maintenance requirements, making them especially valuable on geographies exposed to wide daily and seasonal temperature variations.

www.amorimcork.com

Temperature Sensitivity of Rail Pads

Rail pads must balance stiffness and damping, and for that purpose, two parameters are central, such as:

Shear Modulus: The shear modulus is a measure of a material’s rigidity against shear deformation. A higher shear modulus means that the rail pad is stiffer and deforms less under a given shear stress (load), while a lower shear modulus indicates that the material is softer and deforms more easily under the same stress/load.

Loss Factor: The loss factor is a measure of material damping, representing the ratio between the energy dissipated and the energy stored during cyclic deformation. Materials with a higher loss factor exhibit better damping behavior, as they dissipate more energy.

In this sense, temperature has a strong effect on both parameters. Tests carried out in a temperature-controlled chamber across the range of -20 °C to +40 °C revealed clear trends:

Rubber Pads: As the temperature increases, rubber pads soften. Their stiffness decreases and vibration isolation worsens, leading to higher rail vibrations and noise radiation. At around 40 °C, they are relatively soft and less effective. When cooled to –20 °C, their shear modulus increases by about six times, making them very rigid, but this mainly channels vibration into sleepers and ballast rather than reducing noise. Damping improves at low temperatures, although slightly.

Cork–Rubber Pads: Cork–rubber pads show an even stronger variation in stiffness with temperature, increasing their shear modulus by about ten to thirteen times between 40 °C and –20 °C. The advantage is that they remain stiffer than rubber at high temperatures, limiting the softening effect that amplifies noise. Around 0 °C they reach a peak in damping, with a loss factor up to 0.8, which significantly improves vibration suppression. This combination of higher damping in the transition region and greater stiffness at elevated temperatures ensures more stable performance across the full temperature span.

Implications for Rolling Noise

Rolling noise is one of the most significant sources of railway noise. It is generated when small irregularities on the surfaces of wheels and rails trigger vibrations that propagate through the track structure and radiate into the environment. Because rail pads regulate how these vibrations are transmitted, their response to temperature has a direct impact on noise levels.

Field measurements confirm this effect. Real train pass-bys have shown an increase of 3 to 4 dB(A) when ambient temperature rises from 0 °C to 35 °C.

Predictive models extend this finding, indicating that natural rubber pads may lead to noise variations of up to 6 dB(A) across the full –20 °C to 40 °C range. Cork–rubber pads, by contrast, show a smaller variation of about 4 dB(A). Although both materials are affected by temperature, cork–rubber offers greater stability and predictability.

The reason for this difference lies in the material composition. As rubber pads soften with heat, they lose the ability to control rail vibration. Cork–rubber pads, however, maintain higher stiffness and exploit their damping peak around 0 °C, which together limit noise increases at both high and transitional temperatures.

Cork–rubber pads offer a more consistent and reliable acoustic performance, less variation in passenger comfort, and lower maintenance needs since the track dynamics remain more stable throughout seasonal and daily thermal cycles.

Why Cork–Rubber Pads Offer a More Reliable Solution

Environmental temperature has a decisive impact on the mechanical and acoustic behavior of rail pads. Conventional rubber pads soften at high temperatures and stiffen excessively at low ones, leading to significant noise variations of up to 6 dB(A). Cork–rubber composites, on the other hand, combine the elasticity of rubber with the inherent stiffness and damping capacity of cork. This synergy ensures higher damping near transitional temperatures, greater stiffness at elevated ones, and overall reduced sensitivity to climate fluctuations.

By providing predictable stiffness and superior vibration attenuation across the full range of railway operating conditions, cork–rubber rail pads represent a resilient and effective solution for modern rail infrastructure. They improve noise control, enhance passenger comfort and reduce maintenance requirements, making them especially valuable on geographies exposed to wide daily and seasonal temperature variations.

www.amorimcork.com