railway-international.com

03

'25

Written on Modified on

PJM helps develop highly innovative bogie design

PJ Messtechnik, an accredited test center in accordance with ISO/ IEC 17025, was commissioned by Innofreight to carry out all the necessary steps for the approval of the innovative Y25 bogie.

pjm.co.at

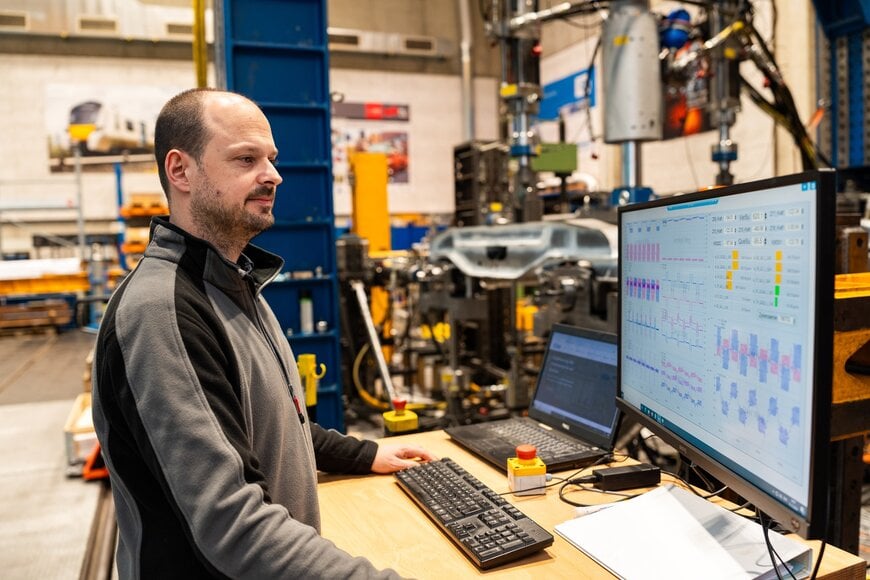

As an ISO/IEC 17025 accredited test centre, PJM also carried out the dynamic test runs. Credit: Manuel Hanschitz, free of charge

Innofreight develops freight wagons, containers and unloading systems and operates 22,000 containers and 3,500 wagons in 20 countries. The Y25 bogie completes the extensive portfolio of the Austrian freight wagon specialist.

The specifications for the new bogie were demanding: the bogie frame was to be manufactured fully automatically and designed to withstand the highly dynamic loads over 4 decades.Due to the expertise of the PJM team, the task was solvable. The structural analysis was carried out using the latest simulation and assessment methods. On the one hand, the standard loads were extended by the results of MBS simulations. On the other hand, the weld seam assessment was carried out using the effective notch stress concept to improve the prediction accuracy and thus enable lightweight construction.

PJ Messtechnik implemented the entire valida tion program in accordance with EN 13749 on the fully developed bogie frame:

→ Structural analysis

→ Static and fatigue laboratory tests at the Institute for Structural Durability and Railway Technology at Graz University of Technology

→ Track tests under extreme conditions to validate the design loads

The result:

→ The bogie is manufactured 100% by welding robots.

→ The weight has been reduced by 5% compared to conventional designs, while at the same time increasing durability. As a result,the load capacity can be increased by 400 kg in future, which means lower costs and greater efficiency combined with greater robustness.

→ Further advantages include less wear on the wheelsets and better braking performance.

In-depth engineering system understanding for rail vehicle components

Thanks to the close collaboration of experienced experts in design (CAD), calculation (FEM), simulation (MBS), measurement technology and certification, PJM has gained a unique understanding of systems and expertise in the product development of structural railway components. A brief overview of the special features:

→ Pioneering lightweight freight wagon construction through topology optimisation

→ TSI-compliant strength analysis of welded steel and aluminum structures

→ Support in the standard-compliant design of welded constructions by our IWE (International Welding Engineer)

→ Certification of the American AAR WABL Committee for strength verifications of railway wheels in accordance with the S-660 and S-669 standards

→ Reducing many time-consuming test runs through efficient comparative multi-body simulations

→ Supporting simulations to minimise wear on wheels and rails

Innofreight develops freight wagons, containers and unloading systems and operates 22,000 containers and 3,500 wagons in 20 countries. The Y25 bogie completes the extensive portfolio of the Austrian freight wagon specialist.

The specifications for the new bogie were demanding: the bogie frame was to be manufactured fully automatically and designed to withstand the highly dynamic loads over 4 decades.Due to the expertise of the PJM team, the task was solvable. The structural analysis was carried out using the latest simulation and assessment methods. On the one hand, the standard loads were extended by the results of MBS simulations. On the other hand, the weld seam assessment was carried out using the effective notch stress concept to improve the prediction accuracy and thus enable lightweight construction.

PJ Messtechnik implemented the entire valida tion program in accordance with EN 13749 on the fully developed bogie frame:

→ Structural analysis

→ Static and fatigue laboratory tests at the Institute for Structural Durability and Railway Technology at Graz University of Technology

→ Track tests under extreme conditions to validate the design loads

The result:

→ The bogie is manufactured 100% by welding robots.

→ The weight has been reduced by 5% compared to conventional designs, while at the same time increasing durability. As a result,the load capacity can be increased by 400 kg in future, which means lower costs and greater efficiency combined with greater robustness.

→ Further advantages include less wear on the wheelsets and better braking performance.

In-depth engineering system understanding for rail vehicle components

Thanks to the close collaboration of experienced experts in design (CAD), calculation (FEM), simulation (MBS), measurement technology and certification, PJM has gained a unique understanding of systems and expertise in the product development of structural railway components. A brief overview of the special features:

→ Pioneering lightweight freight wagon construction through topology optimisation

→ TSI-compliant strength analysis of welded steel and aluminum structures

→ Support in the standard-compliant design of welded constructions by our IWE (International Welding Engineer)

→ Certification of the American AAR WABL Committee for strength verifications of railway wheels in accordance with the S-660 and S-669 standards

→ Reducing many time-consuming test runs through efficient comparative multi-body simulations

→ Supporting simulations to minimise wear on wheels and rails

Innofreight‘s new bogie frame is manufactured fully automatically by welding robots. Credit: Manuel Hanschitz

PJM has a unique system understanding in the product development of structural railway components, due to the close cooperation of experienced experts from design (CAD), calculation (FEM), simulation (MBS), measurement technology and approval.

Credit: Manuel Hanschitz

www.pjm.co.at

Credit: Manuel Hanschitz

www.pjm.co.at