railway-international.com

08

'22

Written on Modified on

Innovative RFID and NFC solutions make rail operations more efficient, safer, more traceable and more reliable

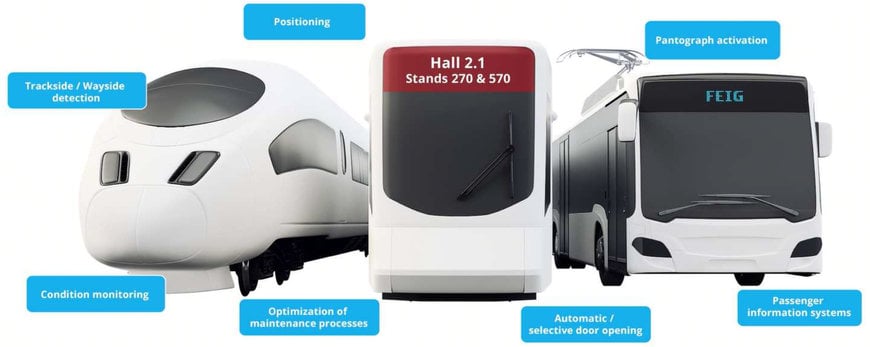

At this year's InnoTrans from 20.09. to 23.09.2022, the companies FEIG ELECTRONIC and smart-TEC will jointly show (Hall 2.1 / Stand 270) what the state of the art is today in the field of Auto-ID in the railway market.

Public transport is not only moving us, it is moving itself. In other words, things are currently in a state of upheaval. No, not the many construction sites on the track - digitalisation is the keyword, so that maintenance, operations, passenger information systems and many other processes work better and more efficiently.

Digitally readable product markings of components, machines and tools requiring maintenance can be recorded fully automatically, error-free and quickly. Maintenance measures and histories are automatically recorded and uniquely assigned to a component. Entire train configurations are automatically recognised at full speed and "married" with data from axle counting systems.

Trains recognise platforms fully automatically and stop precisely at the platform. Train and especially tram or underground train positions are detected very accurately by the vehicle itself. Rail head treatment systems work fully automatically and activate or deactivate themselves at the correct section of the track.

All this is made possible by RFID and NFC technology, which has already been in use worldwide for over 20 years in a wide variety of applications, companies and industries.

“UHF RFID technology enables precise, efficient, environmentally friendly and fully automatic rail head treatment at speeds of up to 100 km/h. It is therefore becoming increasingly important alongside GPS technology. The UHF RFID technology also works independently of tunnels, mountains or other interference. The rail head treatment reduces the noise level and the maintenance costs are lower thanks to reduced wear. So far, the application has proven particularly effective in low-floor vehicles and railcars," says Harald Rebs, Managing Director.

Several live applications will clearly demonstrate what is possible and has proven itself in practice. Of course, innovations will not be neglected. In cooperation with the company REBS Zentralschmiertechnik, the companies will show solutions from everyday railway life. From the robust RFID / NFC transponder for installation in the track bed or on the bogie to the compact UHF RFID reader for mounting under the beam, everything will be shown live.

smart-TEC, the specialist for customised RFID and NFC transponders, will be showing designs specially developed for the railway industry. Optimally adapted to the respective requirements of the railway industry in terms of mechanical, thermal and chemical resistance, smart-TEC has RFID/NFC transponders for almost every application. Regardless of whether weld seams in the rail network, safety-relevant components in the wagon or the entire wagon are to be clearly and traceably marked...smart-TEC has a corresponding solution for this.

www.feig.com