railway-international.com

29

'21

Written on Modified on

Capacitors from TDK for the Future of Railroads and Usher In the Age of the Environment

A series of power electronics capacitors for use in railways and renewable energy systems that enable unprecedented, innovative solutions.

Technical challenges for improving the environmental performance of railroads

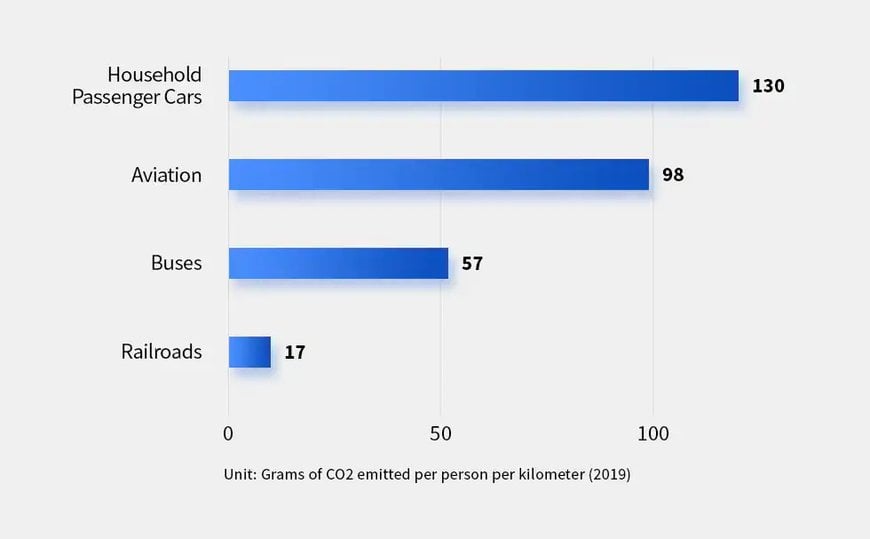

With growing concern over environmental issues, the so-called “modal shift” of freight transportation away from trucks and toward railroads and ships, which are environmentally friendly and capable of mass transport, has been in the spotlight. Railroads, in particular, are arguably the most eco-friendly mode as they emit the lowest amount of CO₂ per unit transported. Expectations for railroads are growing even higher due to the increasing demand for transportation associated with the economic growth of emerging countries.

CO₂ emissions per unit of transportation in Japan

Source: Ministry of Land, Infrastructure, Transport and Tourism

Carbon dioxide emissions per unit transported—an indicator of efficiency—are compared for domestic passenger and freight transport in Japan.

In the age of the environment, railcars are expected to conserve energy more than ever. Key to this end is the advancement of electronic technologies that utilize power semiconductors*2 to control and convert electric power. When electricity is used, part of the energy is inevitably converted into heat. This wasted energy is called power loss, and reducing it as much as possible leads to efficient energy use.

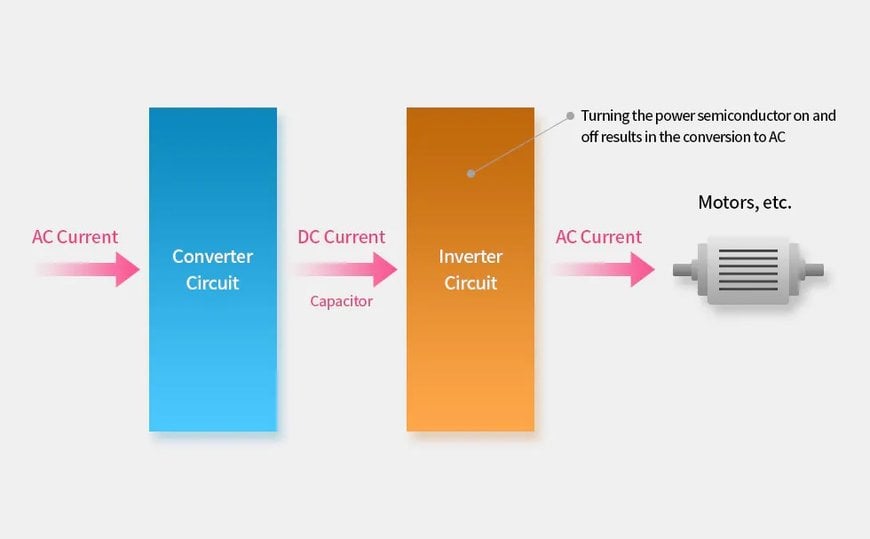

Specifically, power electronics in railcars refers to inverters and other devices used to control motors. Power semiconductors inside inverters convert power from direct to alternating current in order to control the rotation of motors, which helps to reduce power loss. Capacitors inside inverters support the power conversion process from direct to alternating current by smoothing the direct current.

How an inverter works (example)

The supplied AC power (fixed frequency) is first converted to DC. The voltage is regulated to a constant level using a capacitor, then converted back to AC with an inverter. Power semiconductors, which perform the DC to AC conversion, are found inside inverter circuits.

While many types of power semiconductors exist, IGBTs*3 are currently the mainstream device for controlling electric power. Not only is power loss minimized thanks to their high-frequency switching capability, but they can also withstand high voltages and are ideally suited for use with large currents. However, for the progress of power electronics overall, the performance of IGBTs and other power semiconductors notwithstanding, upgrading the capability of capacitors*4 used in conjunction with them is also a critical issue.

A groundbreaking power electronics capacitor solution that shatters conventions

Capacitors for use in power electronics are especially required to be compact and lightweight to save space in railcars and to be reliable and durable enough to withstand vibration and harsh temperature environments. Due to the nature of large infrastructure systems, capacitors for railcars are generally designed and manufactured to customer specifications every time. Custom-made products, however, require longer development times and incur higher costs.

ModCap, developed by TDK, is a family of power electronics capacitors designed to complement IGBTs. Breaking industry norms, it is the first of its kind to be successfully standardized and modularized. Three key features differentiate this product.

First is the reduction of size and weight achieved by implementing the latest, state-of-the-art design rules for capacitors and by optimizing the mechanical coupling between ModCap and semiconductors. ModCap replaces the traditional customized MKK solutions with a rectangular plastic enclosure, delivering the highest levels of downsizing, weight reduction and energy density. This contributes to the overall size reduction of power systems in railroads.

Second is its superior reliability and durability. A hot spot (the point with the highest internal operating temperature) of up to 90°C can be tolerated, whereas 85°C was the limit in the past. It also meets the highest fire and smoke safety standards for railroads.

Third, it is the first in the industry to achieve standardization and modularization. Individual needs that required custom designs in the past can now be fulfilled by a standardized lineup with a broad range of specifications. Time-to-market has been dramatically shortened, while cost has been reduced substantially.

www.tdk.com