Zeleros and ArcelorMittal test the performance of steel for hyperloops

A new, unique ultra-high-speed testing facility has been designed to evaluate the performance of materials needed to build and operate ultra high-speed transport systems.

- Zeleros’ and ArcelorMittal’s work allows both companies to optimise the design and selection of steels to use in hyperloop vehicles and infrastructure

- Zeleros releases a short film to mark latest phase of Hyperloop development

Zeleros, the European company developing the scalable hyperloop, an ultra high-speed mobility solution for transport of passengers and goods, and ArcelorMittal, the world’s leading steel and mining company, have carried out trials to analyse the behaviour of steel grades for optimal use in hyperloops.

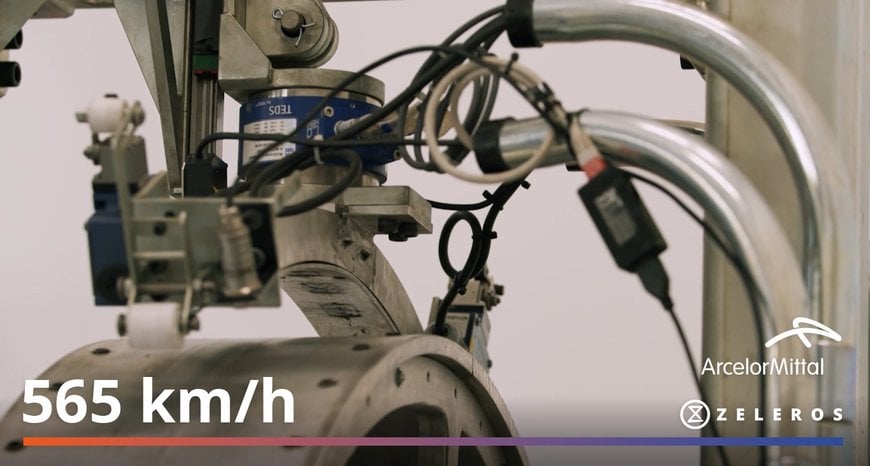

A testing facility in the form of a spinning wheel that can reach linear speeds of up to 500km per hour has been designed and built at ArcelorMittal’s Rail Excellence Centre in Spain, to test how certain steels perform in ultra-high-speed conditions, prior to testing on a scaled hyperloop track. The results provide data to further advance the selection of the best steels for hyperloop use, considering safety, energy efficiency, cost and scalability as the main decision criteria.

A relevant collaboration for Zeleros’ scalable hyperloop

Zeleros and ArcelorMittal have been working together since 2017. Since then, experts from both companies – including all of ArcelorMittal’s R&D centres - have jointly developed studies to analyse the way in which materials behave in high-speed conditions, measuring the effects of key characteristics for hyperloop technology, such as the electromagnetic properties of steels (hyperloop designs propose the use of magnetic levitation). As part of the collaborative work between the two companies, ArcelorMittal’s rails business in Europe – ArcelorMittal Europe – Long Products, Rails and Special Sections - has developed new products with improved guiding and braking performance, as part of the wider co-engineering project between Zeleros and ArcelorMittal.

“To reach Zeleros' vision of building a scalable hyperloop, including the braking, guiding and levitation technology in the vehicle, this collaboration is key. Thanks to the continuous improvement of steel, we can radically reduce infrastructure costs and assure energy efficiency and infrastructure viability”, stated Daniel Orient, Zeleros’ CTO.

“The work we have been doing with Zeleros reflects the importance we place on our involvement in innovative projects using steel in infrastructure and transportation, and that contribute to reducing CO2 emissions”, said Nicoleta Popa, Portfolio Leader of Construction Applications, Infrastructures and Long Products of ArcelorMittal Global R&D.

“The multidisciplinary ArcelorMittal team for the structural, mechanical and electromagnetic aspects, proves the strength of our approach for such complex innovative projects, both in defining new products and in developing new solutions” said Frederic Painchault, Head of marketing of Global automotive & Mobility solutions.

Besides hyperloop, ArcelorMittal has participated in studies of materials for other applications developed by Zeleros, such as the SELF (Sustainable Electric Freight-forwarder), conceived to move standard intermodal containers in a faster, automated and sustainable way within ports, for which the test track is currently under construction in the port of Sagunto in Spain.

Likewise, the objective of Zeleros is to advance in the construction of mobility solutions that are sustainable and efficient like hyperloop and SELF, accompanied by partners with extensive industrial knowledge, as confirmed by the material studies carried out with ArcelorMittal.

www.zeleros.com