InnoTrans 2024: Innovative Mobility Solutions from ZF

InnoTrans 2024: Innovative Mobility Solutions from ZF for Trains and Buses.

www.zf.com

- Repowering with ZF ‘EcoWorld 2’ rail transmission significantly reduces fuel consumption and maintenance costs

- Leading digital solution ‘connect@rail’ for predictive maintenance of driveline components and rails

- ZF Group celebrates 100 years of rail technology

- Powerful ‘CeTrax 2 dual’ electric central drive for buses with high passenger numbers or challenging topographies

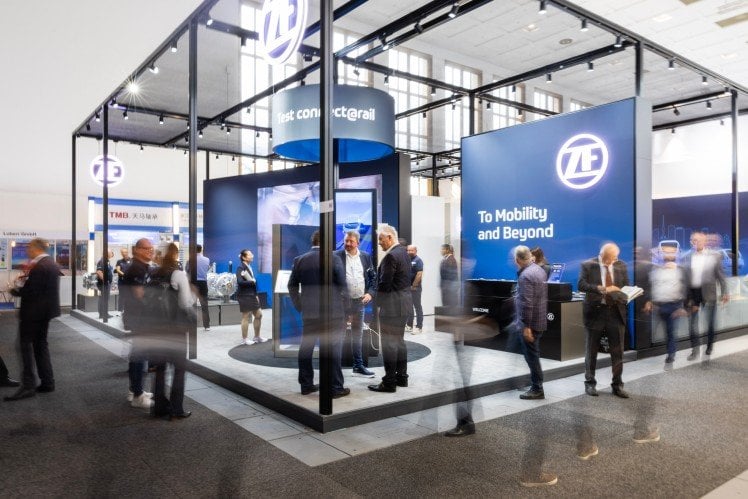

Whether train, bus or shuttle, electric or non-electric drive, mechanical or digital solution: ZF will be presenting its latest mobility solutions for public transport at the InnoTrans 2024 trade fair in Berlin from September 24 to 27. ZF’s global aftermarket network offers comprehensive maintenance and repair services, including for products from third-party manufacturers. This year, ZF is celebrating a special anniversary: a century of rail technology.

In its anniversary year, the technology group ZF shows a broad portfolio of conventional and electric drives, chassis technology, digital solutions and aftermarket services at booth 580 in hall 20 of InnoTrans, the leading international trade fair for transport technology.

Prof. Dr. Peter Laier, ZF Board Member for Commercial Vehicle and Industrial Technology, said:

“Public passenger transport by rail and road is an important cornerstone of our daily mobility.

“As an innovative and broad-based technology partner, we support our customers in making this mobility more efficient, safer and more sustainable.”

ZF Rail Technology: 100 Years, Countless Successes

Laier continued:

“The sustainable mobility of the future needs a strong rail system.

“That’s why our Group has been developing reliable and powerful technologies for the rail industry for 100 years now and will continue to do so in the future.”

ZF first developed a drive system for railcars in 1924: The “Soden TS18.5” transmission was the adaptation of a technology that had primarily been developed for passenger cars. Even today, ZF can offer its rail customers proven technology from other application areas: For example, the EcoWorld 2 six-speed powershift transmission with integrated reversing function and hydraulics is based on a proven bus transmission and is now an ideal solution for repowering diesel railcars. Its use can save up to 20 percent fuel compared to hydrodynamic rail transmissions. In addition, maintenance costs can be reduced and travel comfort increased.

With its running gear technology and the digital condition monitoring system connect@rail, the company is also underlining its position as the preferred technology partner for vehicle manufacturers, fleet operators and transport associations. As a comprehensive condition monitoring system, connect@rail combines digital expertise, integrated sensor technology, advanced data analysis and intelligent connectivity for rail transportation. Because it identifies damage to the drivetrain and track infrastructure at an early stage, connect@rail enables efficient maintenance planning. This avoids breakdowns, increases safety and helps to make rail mobility as smooth as possible.

ZF Bus Technology: From Proven Technology to Intelligent Systems

ZF presented the EcoLife CoachLine six-speed automatic transmission for intercity buses and coaches with engine torques of up to 2,800 Nm back in 2022. At InnoTrans, it is clear that the powershift transmission continues to set standards for efficiency and driving comfort, especially on interurban routes and challenging mountain roads. Thanks to its dual cooling system, maintenance requirements are reduced, which has a positive effect on operating costs over the entire service life of the transmission.

With the CeTrax 2 dual, ZF presents an attractive drive concept for all-electric public transportation. The electric central drive with a continuous output of 380 kW integrates modular and in-house developed components in an innovative system solution. Its compact size saves valuable space on board, while the low weight supports high power and torque values with improved efficiency. Thus, CeTrax 2 dual offers amazing performance even with high passenger numbers and/or challenging topographies in the city or in the countryside.

ZF not only offers bus manufacturers and transport authorities outstanding technology, but also supports them in optimizing their processes. The intelligent fleet management system ZF Bus Connect has functions such as Vehicle Health or OptiTire as well as the seamless integration of planning, scheduling, ticketing, passenger information and billing. In this way, ZF ensures the reliability and efficiency of the vehicles – and thus helps to improve customers’ profitability.

ZF Mobility Solutions: Customized Mobility Solutions of the Future

Broad portfolio, system expertise, strong global partners: Under the name ZF Mobility Solutions, the company offers services for engineering, consulting and holistic mobility solutions. At the ZF stand, interested parties can find out which concepts our teams of experts can develop for specific applications and tasks, particularly in the rail sector.

ZF Aftermarket: Local Service Thanks to Global Presence

Through the Aftermarket division, ZF ensures smooth passenger transportation with important services such as diagnostics, overhaul and spare parts supply. In this way, the company ensures the reliability of its products over their entire service life – worldwide and around the clock.

And that’s not all: ZF offers maintenance and repair for its own products as well as for third-party products, so that fleet operators can obtain solutions from a single source at ZF. A European rail competence center not only covers ZF products, but also market alternatives and retrofit solutions. With its cross-brand and cross-system expertise, ZF provides its customers with a wide range of services, including reverse engineering and lifecycle management. ZF’s global support is further strengthened by the local and partnership-based network. This enables ZF Aftermarket to respond flexibly to customer needs and meet the highest performance standards with customized solutions.

www.zf.com